Nonoxide Ceramics

Department

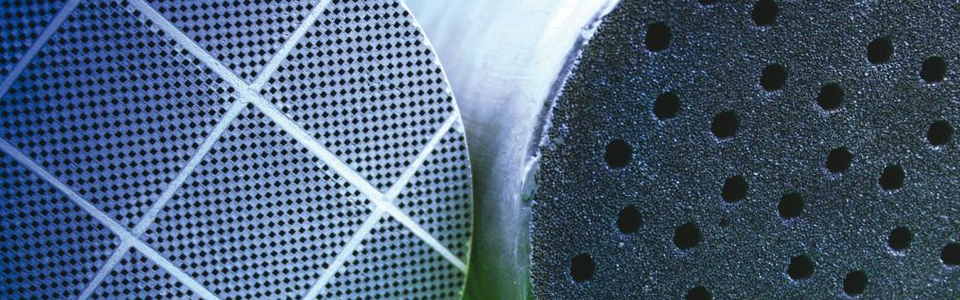

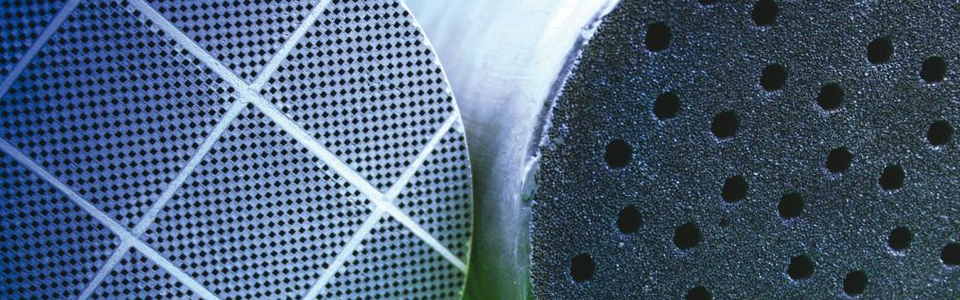

Nonoxide ceramics are characterized by a number of extraordinary properties. Among the carbides and nitrides of boron, aluminum, silicon, titanium, and zirconium, silicon nitride and silicon carbide ceramics are at the core of R&D efforts at Fraunhofer IKTS. Special attention is paid to the extremely high thermal, wear, and corrosion resistance as well as the specific electrical and thermal properties of nonoxide ceramics. Apart from classic monolithic ceramics, ceramic matrix composites (CMCs) and corrosion-resistant coatings as well as structural ceramics with tailored electrical functions (e.g., thermoelectric materials) are investigated. Applications can mainly be found in mechanical engineering, chemical and energy technology, and microelectronics.

Another core topic is ceramics with controlled porosities and cellular structures for filter, catalyst, and substrate applications in the automotive industry, environmental engineering, biotechnology, process engineering, and metallurgy.

The department develops and optimizes materials and components for specialized applications and investigates interactions with manufacturing processes in close cooperation with the Materials/Components department.

Current activities at Fraunhofer IKTS in the area of structural ceramics with tailored electrical functions include development of industrial manufacturing processes for zirconium carbide materials with high stability under vacuum as potential substitutes for tungsten and molybdenum materials in high-temperature applications. Other heating or temperature sensor tasks in combination with structural functions can be fulfilled with specially modified heating elements made of various ceramics.

In the field of carbide ceramics, Fraunhofer IKTS has, for example, developed a process for producing complex SiC components by pressureless casting. Materials made with this cost-effective process can replace conventional materials in pump impellers, nozzles, mills, recuperators, and burners. Thanks to the outstanding chemical, thermal, and tribological properties of SiSiC, increased machine service life and/or productivity can result.

Ceramic matrix composites (CMCs) can replace metals especially for use at high temperatures or for enabling processes to be carried out at much higher temperatures. Fraunhofer IKTS is currently expanding the coating facilities. Homogeneous and continuous coating of endless fibers and rovings as well as three-dimensional woven fabrics will be possible in the future. New possibilities in terms of coating technologies and variations will also be created.

In the field of porous ceramics, LPS-SiC was developed as a material for use in particulate filtration and qualified for mass production of diesel particulate filters, mainly for off-road applications. Industrial introduction of open-cell particulate filters and catalysts for high-efficiency wood-burning appliances, among other things, represents another milestone in our work.

Services offered

- Technology-oriented development or improvement of nonoxide ceramics, especially silicon nitride and silicon carbide ceramics and composites

- Development of short-fiber or long-fiber ceramic matrix composites and corrosion-resistant coatings (environmental barrier coatings)

- Development of porous and cellular ceramics with pore sizes in the nm to mm range

- Adaptation of mechanical and tribological properties, electrical and thermal conductivity, chemical corrosion resistance, and high-temperature resistance

- Concepts for cost optimization of ceramic raw materials, materials, and components

- Process development, manufacturing, characterization, and testing of prototypes for applications with mechanical, chemical, thermal, and electrical loading