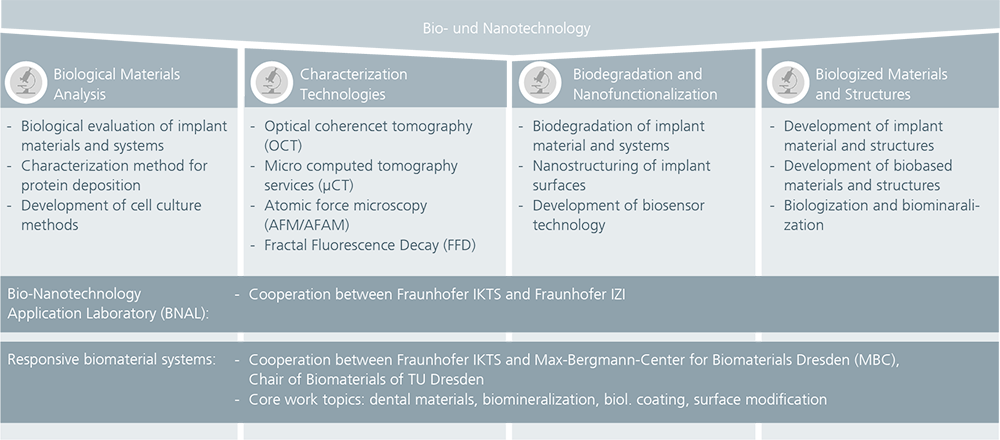

Bio- and Nanotechnology

Department

Implant material, material characterization and non-destructive testing in bio- and nanotechnology

At the intersection of materials science, biology and materials analysis, the Bio- and Nanotechnology department of Fraunhofer IKTS develops further and optimizes implant materials and their surface properties by developing and using methods of biological material characterization as well as non-destructive test processes and systems. Beyond the scope of contract research, (in-line or stationary) test services are also part of the department’s portfolio.

The researchers work at our locations in Dresden and Leipzig and are always in close contact with the client. The aim of our activities: To convert results of fundamental research faster into marketable solutions. This applies to medical equipment in general, as well as to the assessment of the biocompatibility and immunological compatibility of implant materials in particular. Our labs and technical centers are optimally equipped to ensure that research processes are efficient and meet the quality requirements.

A close look at biomaterials and implant materials

The characterization of implant materials and components is one of the department’s core activities. From a technological and regulatory perspective, innovative implants are among the most challenging medical products. When it comes to selecting a suitable implant material and materials for the components of medical products, the critical minimum requirements must be analyzed and complied with at all times.

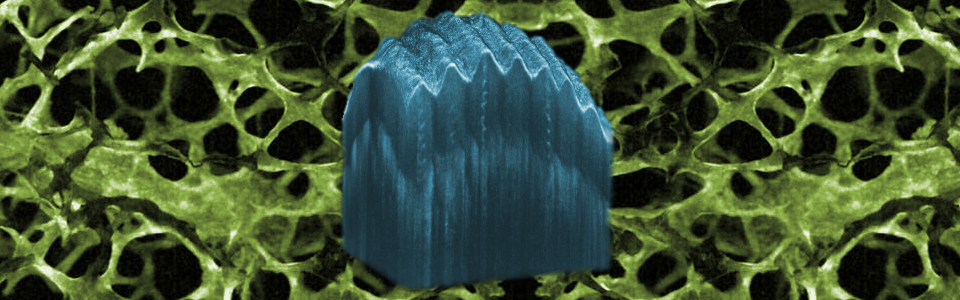

The implant – or implant material – is examined with regard to its geometry, material defects (e.g. cracks, blow-holes, pores, delamination), mechanical stress, hardness, microstructure and other properties, from the macro- to the nanoscopic scale. The researchers apply processes, such as atomic force acoustic microscopy (AFM/AFAM), ultrasonic microscopy, optical coherence tomography (OCT) or ellipsometry. In order to map the degradation patterns of materials as realistically as possible ex-vivo, the Bio- and Nanotechnology department is developing long-term test stands with various liquids that behave like body fluids.

The focus is also on additive manufacturing (AM) methods, which are analyzed and monitored with optical coherence tomography (OCT). The integrated test and process monitoring technologies developed by Fraunhofer IKTS enable the additive manufacturing methods to make use of their full potential for bottom-up production with a batch size of ‘one’.

Biointerface: interaction between biological and implant material

Another area of activity for the Bio- and Nanotechnology department is the development of methods and technologies for evaluating biological and immunological properties of implant materials and other medical products. By using non-destructive measurement and test methods, it is possible to make detailed statements on the interaction between biological and artificial materials. This allows for the improvement of the mechanic stability and service life as well as the biological and immunological compatibility of materials.

The IKTS researchers are also working on modifying material and sensor surfaces, and adding specific functionalities to them. To achieve this, the surfaces are adapted with the help of biomolecules, linkers and nanoparticles, depending on the desired functions. In this regard, the functionalization and application of diamond nanoparticles is of particular importance. Furthermore, the biologists, physicists and engineers develop biological sensors, including the corresponding sensor packaging, mostly within the framework of European cooperative research projects. In Dresden, the Bio- and Nanotechnology department works closely with the Max Bergmann Center for Biomaterials (MBC).

The combination of all these scientific competences from the field of material and measuring technology development translates into novel approaches which create added value for bio- and nanotechnology developers and manufacturers.