Fraunhofer IKTS designs and develops electrolysis processes. Furthermore, they can be tested in laboratory and pilot-plant scale and transferred to industrial scale. Applications include the treatment of contaminated wastewater and process water from mining, industrial and power generation processes, the recovery of raw materials as well as corrosion and scaling in geothermal plants.

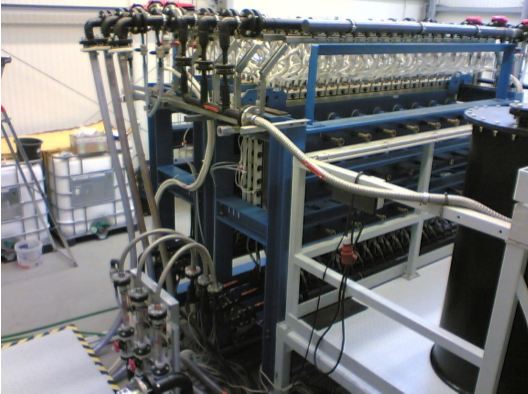

We have modern measurement technology and self-developed electrolysis cells from laboratory to pilot-plant scale. In our technical test facility in Rainitza, water treatment processes can be tested on a pilot scale in industrial electrolysis cells. For exposure tests and electrochemical in-situ investigations in deep geothermal energy, we have, among other things, a TÜV-approved mobile test stand.