AI-assisted prognostics and condition management for electronics

Current research

Not only since the rise of the Internet-of-Things (IoT), the demand for reliable, trustworthy and smart electronics has been steadily increasing. Prognostics and health monitoring (PHM) offers cost-efficient and fast electronic system monitoring and damage-based maintenance planning. Continuous monitoring of electronic systems generates a large amount of data. Ideally, this data should be evaluated without storing it permanently. Machine learning (ML) algorithms, an area of artificial intelligence, are suitable for this purpose.

New approach for real-time prognostics

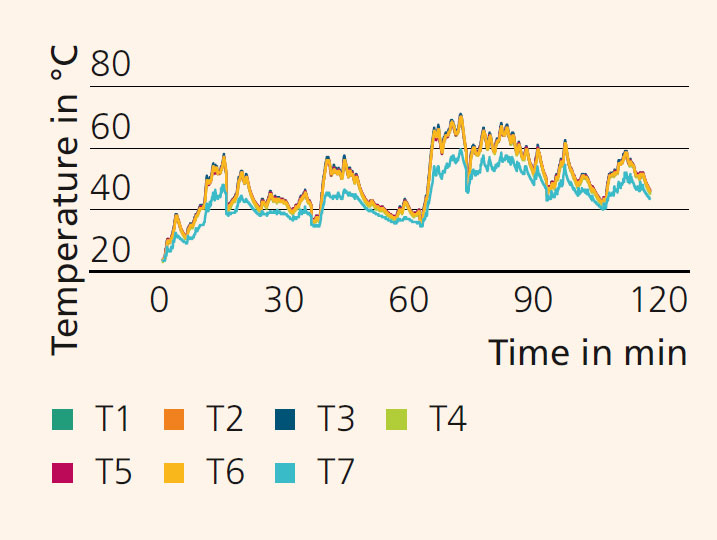

The methodology we propose here has the potential of becoming a viable solution for online monitoring. As a test application, the power module of an electric bike was chosen (top image). The remaining service life was deduced directly from the thermal loads that occur during the ride (bottom figure).

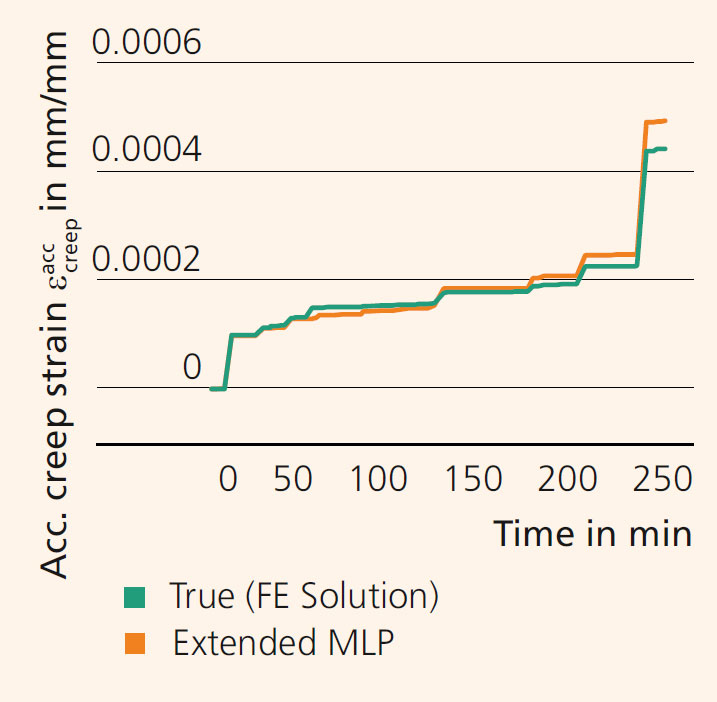

A large dataset of synthetic temperature-time profiles was generated in order to perform the AI training. The damage of solder joints under these temperature loads was evaluated with finite element analysis (FEA), based on which a multilayer perceptron (MLP) model was trained. Temperature features and corresponding creep increments constitute a training dataset in this case. The accuracy of the trained model is further increased through transfer learning from field tests (mission profile). The remaining useful lifetime (RUL) of this discrete power electronics component under service is then estimated based on the determined lifetime model.

The key achievements of this method are: (1) the extraction of features from temperaturetime data, which reduces the need for data storage, (2) efficient training using synthetic data and easy extension to limited real-world data, as well as (3) excellent forecasting capability in real time.

The graph below shows the impressively accurate forecast of creep of the MLP in comparison with the data from FEA. The average error as determined from the test data set is only 6.7 %.

Using the power electronics of the e-bike motor unit, we were able to demonstrate that this methodology is a significant step towards an intelligent PHM implementation. It provides a real-time forecast of the remaining service life – a feature that is critical in other safetyrelevant applications, such as in the rail or automobility sectors.

Sponsored by