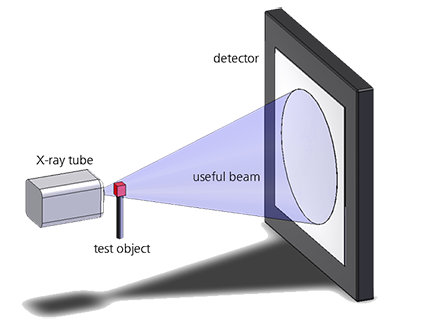

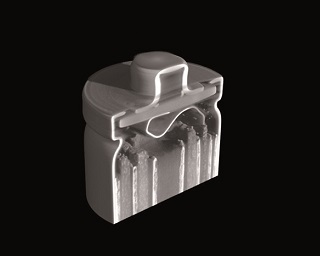

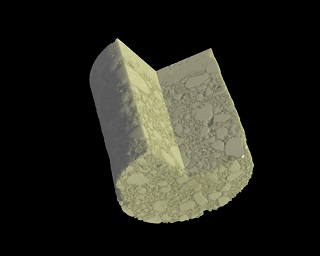

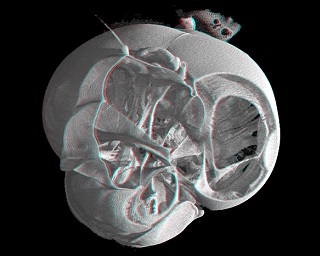

At Fraunhofer IKTS in Dresden, industrial micro-computed tomography (micro-CT) is an established analysis method for component inspections and small series testing. However, it is also becoming increasingly important in the examination of artistic and cultural goods. Micro-computed tomography is an ideal X-ray CT method for detecting inclusions, cracks, pores and other material inhomogeneities within an arbitrarily shaped object and thus for performing pore analyses, void analyses, dimensional accuracy or completeness analyses. Micro-CT enables non-destructive three-dimensional inspection of objects with a high spatial resolution.

The X-ray CT device set up at Fraunhofer IKTS can be adapted to the respective customer-specific requirements. Thus, very small components, for example from electronics, as well as large objects, such as components from the automotive industry but also art objects or fossils, can be examined.