Water and waste water technology

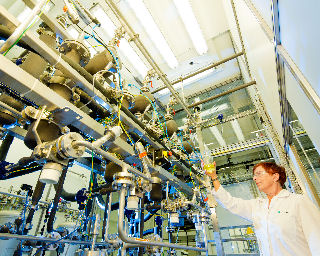

Pilot plants and lab facilities

The sites of Dresden and Hermsdorf in Germany offer a total of approx. 3,200 square feet of well-equipped areas with labs and pilot plants. These include specialist labs for handling biogenic and explosive materials, as well as a radionuclide lab 10E4 x FG for radiotracer tests and process analyses with radioactively contaminated material.

Sample production

Once membrane development has successfully completed on a lab scale, membrane technologies are transferred to larger, industrially relevant geometries and pilot production is set up. This step allows to develop processes for subsequent production on an industrial scale. Furthermore, pilot plants are equipped with membranes to evaluate the respective use case on a realistic scale.

Application Center for Membrane Technology, Schmalkalden

Fields of activity include client- and application-specific membrane testing and piloting processes, the development and construction of membrane housing prototypes and test plants, the development of cleaning strategies, the implementation, support and assessment of field tests, as well as the development of concepts for integrating membrane processes in the client's production cycle.

Application Center for Bioenergy, Pöhl

When it comes to developing technologies in the field of biomass, often linked to the treatment of process water and selective material separation from aqueous solutions, it is usually impossible to transfer lab results directly into daily industrial practice. The aim of the Application Center for Bioenergy is to close, by technological means, the divide separating lab work and practical application. Various test areas and facilities are provided for research projects and industrial contract research.

Technical pilot plant for mining water, Rainitza

With the purpose of technical testing of the RODOSAN® process for electrochemical sulfate separation and mine water cleaning, the site of GWRA Rainitza hosts a pilot plant. It has a modular design and achieves a treatment capacity of up to 10 m3/h (approx. 2,600 US gallons per hour). The pilot plant enables sulfate separation of up to 65 %, with full separation of Al and Fe. It includes, among other things, a control station, an on-site lab, and comprehensive logistic facilities to implement different testing programs and process variants simultaneously.

Test stands for deep geothermal processes

For corrosion and scaling tests, as well as for tests on the electrochemical conditioning of geothermal brine and water, including raw material recovery, in-situ test stands are available at the sites in Neustadt-Glewe (Mecklenburg-Western Pomerania) and Pullach (Upper Bavaria). These are operated in parallel next to the respective exploitation wells. They are equipped with the appropriate sensors, control and safety equipment and provide a large number of opportunities for experimenting.