In the context of sustainable use of the oceans, Fraunhofer IKTS is working on environmentally friendly and durable ceramic materials for sensors, bearing and wear components as well as coatings for maritime applications. On the one hand, this allows the service life of products to be extended through greater corrosion and abrasion resistance and improved antifouling behavior. On the other hand, the leaching of harmful substances can be avoided and their input into the environment reduced. In addition to the material properties, we take into account relevant environmental parameters, such as oxygen content, UV radiation, pH value, flow velocity or temperature during material development, which are recorded simultaneously.

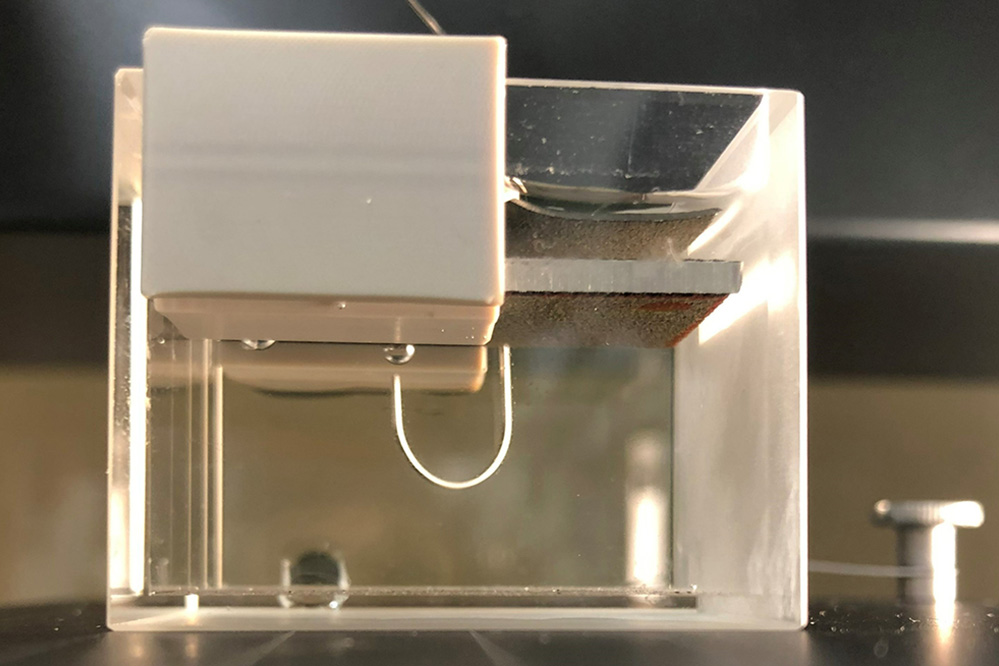

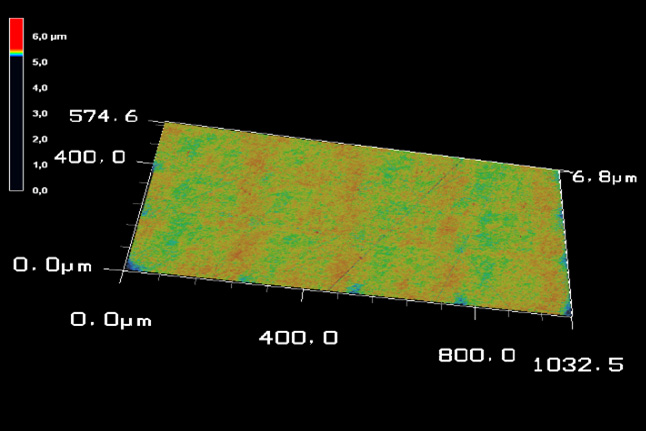

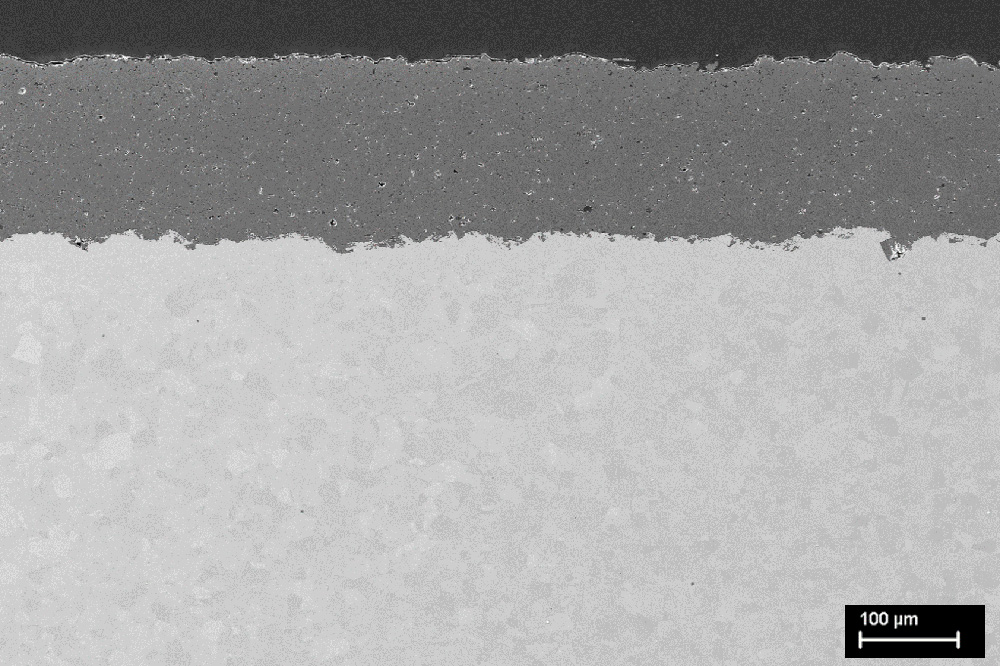

In order to precisely determine the influence of these parameters, we take advantage of the possibility to store and subsequently analyze coatings and components under real maritime conditions at our site in Rostock. This ranges from material testing in closed systems (mesocosm) to field tests in the Warnow estuary or directly in the Baltic Sea. For this purpose, we are establishing and validating new measurement and characterization methods tailored to maritime conditions. Surface analysis is of particular importance here, because the interface is subject to the strongest influences and therefore, largely determines the durability of solids (in the maritime environment). Consequently, we pay special attention to the determination of morphology (surface topography and internal microstructure in the near-surface area) and chemical composition. We have numerous analysis and measurement methods at our disposal for this purpose: