Ceramic phosphors change their optical properties under the influence of ionizing radiation, including low-energy electron radiation, and temperature. Therefore, they are suitable for dosimetry, i.e. measuring the absorbed radiation dose during electron irradiation (e-beam treatment). In this way, the irradiation process can be controlled and its quality assured.

Dosimetry in 1D, 2D and 3D

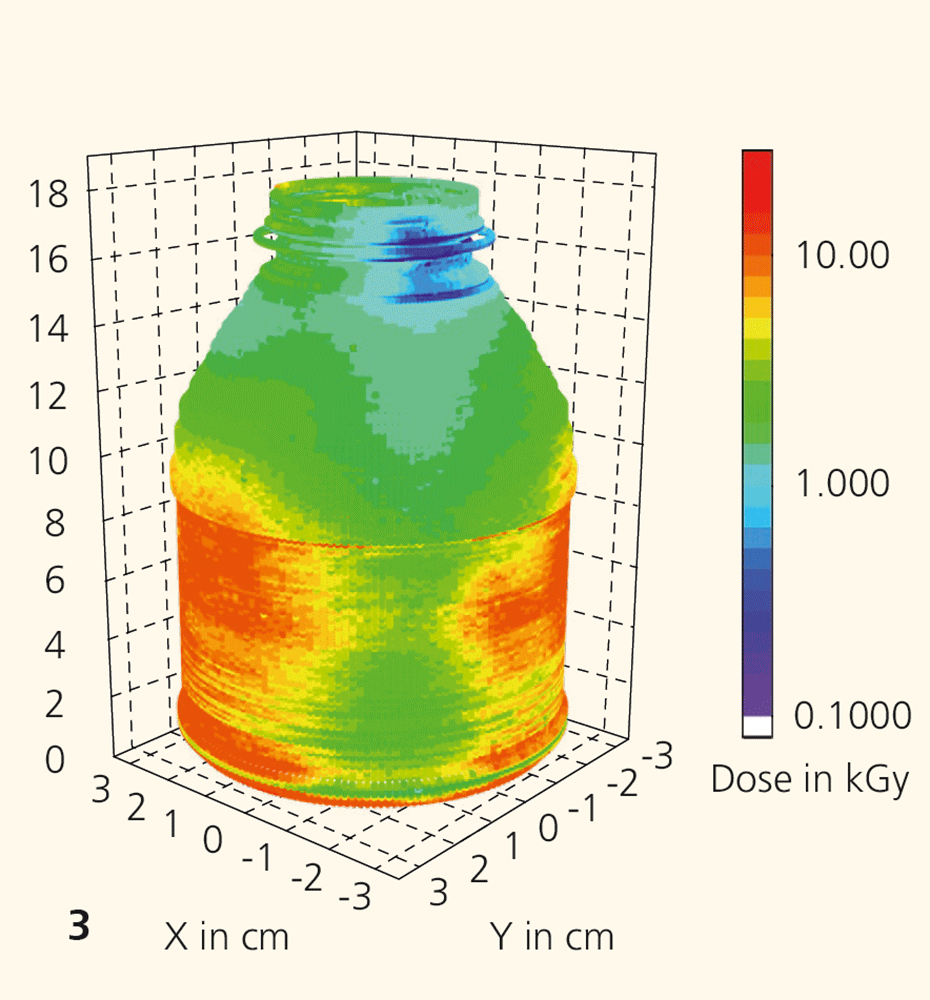

The luminescent materials developed at Fraunhofer IKTS show a luminescence under pulsed near-infrared excitation, the decay time of which depends on the dose of an applied electron irradiation. Optical interrogation of this luminescence decay time thus allows conclusions to be drawn about the applied radiation dose in the range of 0.1 to 30 kGy.

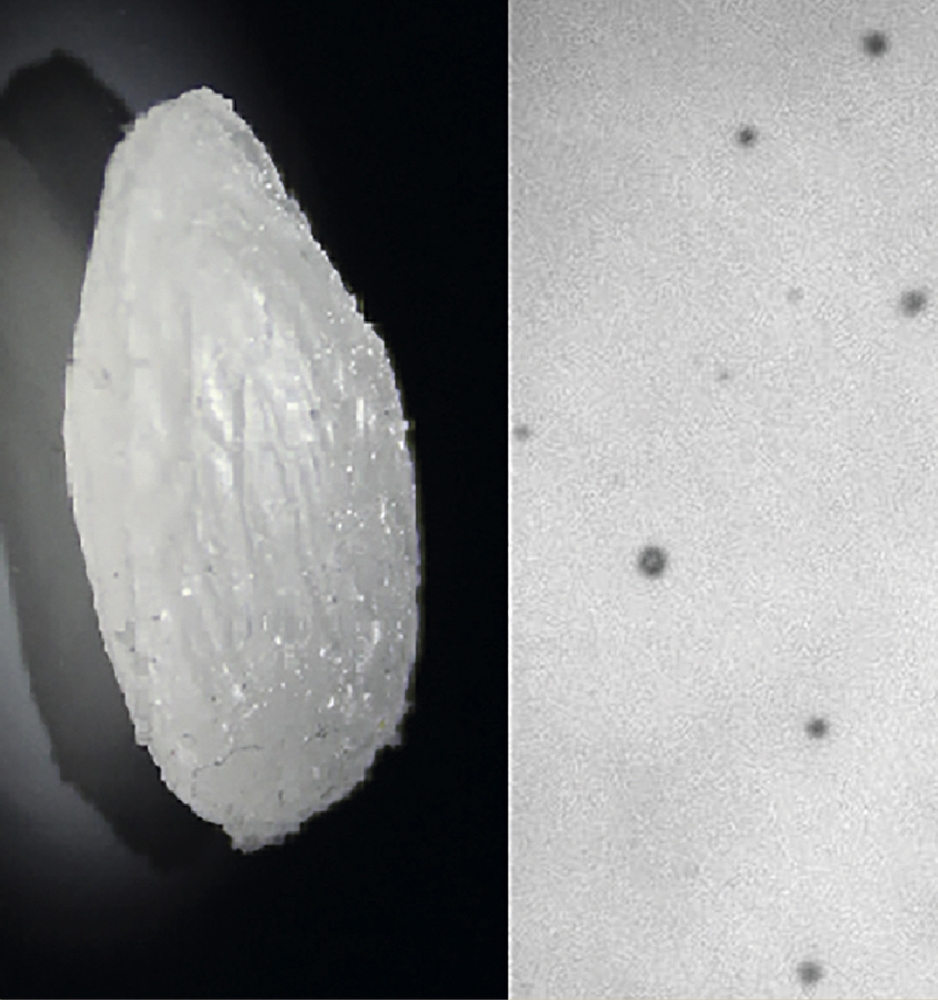

The ceramic luminescent materials are present as powders, which allows for different insertion and application methods: The μm-sized particles can be applied as an ultra-thin dosimeter or embedded in a material. Thus, dose information such as the dose depth profile can be accessed at an unprecedented dose spatial resolution inside a product, at any location of a particle, along a line (e.g., dose depth profile), in a cross-sectional area, or on complex product surfaces.

New fields of application

- Preparation of dosimetrically active product twins from polymers while preserving the original radiation penetration capability

- Chemical bonding of phosphor particles to fibers for medical cell carriers to control sterilization processes

- Coating of surfaces with fluorescent inks or varnishes to produce 2D or 3D dosimetry maps

Services offered

- Optical characterization of the phosphors

- Production of dosimetrically active test products for installation testing of electron irradiation facilities, setup of new irradiation processes or routine process control

- Development and construction of process-integrated devices for the readout of dose information

Technical infrastructure

- Electron irradiation system EB-Lab 200 incl. dosimetry system

- High-resolution optical microscopy

- High-resolution spectroscopy (also time-resolved)

- TL/OSL measuring device lexsyg smart (TL: thermoluminescence)

- Marking system (single-nozzle printer) Tippl MS 1000

- Portable measuring instruments for luminescence decay time of dose-sensitive phosphors