Electronics and Microsystems

Areas of application

Electronic devices and components

As end users‘ demands continue to grow, so too does the need for components that guarantee the utmost reliability and most durable lifespan, as integration density and miniaturization continue to increase – even under the most adverse operating conditions. Their specific physical properties give ceramic devices tremendous advantages for high-frequency and high-temperature applications. Fraunhofer IKTS develops customer-specific solutions for solid and flexible substrates, passive components and integrated circuits. A particular specialty at IKTS is embodied by polymer ceramic composites that link the process capabilities found in plastics with properties that are typical of ceramics, such as durability and temperature resistance. These composites are especially well-suited for use in highly durable components and system encapsulations.

Sensors and sensor systems

Fraunhofer IKTS offers single-source, complete sensor solutions for use in chemical, electrochemical, electrical, thermal, acoustic, electromagnetic, mechanical, and optical sensor technologies. Building on the synthesis of functional ceramic materials and the processing of commercial materials, Fraunhofer IKTS develops sensor components for applications in chemical, process, environmental, energy, and test engineering. Depending on the requirements, these sensor components can be furnished with calibrated evaluation electronics for one or multiple parameters and are integrated into the system environment. Fraunhofer IKTS assists customers and project partners along the entire process chain: from materials synthesis and adaptation to the integration of the entire system into existing process and systems structures.

Industrial and automotive sensor systems represent one focus in this regard; so too is the non-destructive testing of metals, ceramics, and composites as well as carbon fiber-reinforced composites. The institute has honed its existing expertise in the configuration of high-temperature resistant sensor solutions based on ceramic substrates.

Related Links

Electronic microsystems

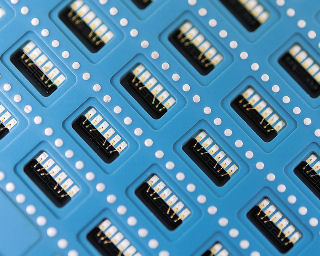

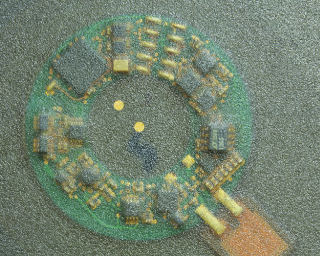

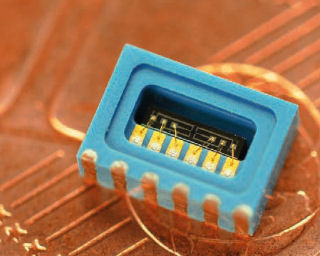

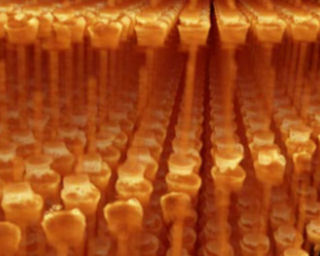

Due to their high temperature resistance, mechanical strength and the possibility to produce them in multiple panels, ceramic packaging solutions offer the benefit of being an ideal integration platform for microoptical, microelectromechanical (MEMs) and sensory systems. By enhancing them with actuators, heating and cooling elements, fluid elements and other functionalities, scientists can tap into entirely new areas of application for highly integrated products. These can be integrated on a three-dimensional basis by using the latest thick-film, multilayer (HTCC, LTCC) and thin-film technologies, and they can be miniaturized all the way down to the wafer level. These sensors can also be fully embedded into structural components.

Intelligent materials and systems

Functionality does not necessarily mean complexity. Fraunhofer IKTS works with smart systems in which different components are integrated into a total system. However, the material itself can also execute controllable functions directly. To do so, staff at Fraunhofer IKTS researches and studies the extraordinary physical properties of materials. Known as “smart materials”, they can respond to physical parameters autonomously, combining electrical and mechanical functionality, e.g. to execute mechanical movements within the most confined spaces. These properties lend themselves superbly for use in microfluid technology, optics and laser engineering, as well as micromechanical systems. IKTS researchers engineer such materials, characterize their properties in meticulous detail, test them, and integrate them into components and systems.

Material parameters and reliability

Shortened development cycles and increasing complexity at the component and systems levels make the reliability of nanoelectronic and microelectronic systems a central challenge. The scientists at Fraunhofer IKTS study and evaluate functional and heterogeneously integrated systems in nanoelectronics and microelectronics, as well as microsystems technology. At the heart of these endeavors is the effort to identify and measure key material parameters on a variety of scales, using mechanical and thermal test procedures as well as high-resolution microscopy. These determinations are used to subsequently derive design rules for robust components. Drawing on a broad spectrum of in situ measurement procedures, specific material and joining requirements can be evaluated and optimized in real time in order to provide the appropriate parameters for the simulation. The knowledge acquired in this manner about materials and joining technologies, as well as the mechanisms of degradation and failure, form the basis for an improved level of reliability.

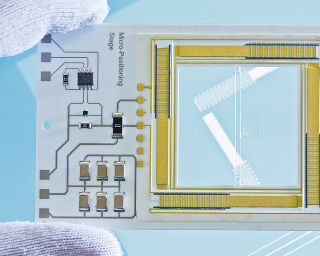

Printing inks and flexible electronics

Flexible substrates made of polymers represent an increasingly significant platform for the architecture of electronic circuits and the integration of microsystems. The temperature resistance, which is limited to a maximum of 200 ºC, necessitates the application of the low-sintered inks for metallization and functional coatings. In the process, the scientists apply techniques, such as screen, inkjet, and aerosol printing. Fraunhofer IKTS offers nanosuspensions for this made from a variety of materials, such as Ag, Au, Pt, Cu, ITO, CNT or graphene. These layers are then tested for their adhesion, conductivity, and bondability using viable serial production and existing full-scale production methods.