Within the framework of the Competence Center ”Thermal Coating Processes” (Fraunhofer Institutes IWS and IKTS, members in the German Society of Thermal Spraying GTS e.V.) the IKTS deals with the development of customized powders for coating technologies (spray powders for thermal coating processes, targets for PVD processes). Hard materials with metallic bond and ceramic materials as well as with polymer components are the basis for these spray powders.

Products and services offered

- Development and manufacturing of spray powders (material development, raw material screening, synthesis/adjustment of different phase configurations [sintering])

- Manufacturing and processing of fine and nano-disperse raw materials, preparation of synthesized raw material mixtures according to customers’ requirements

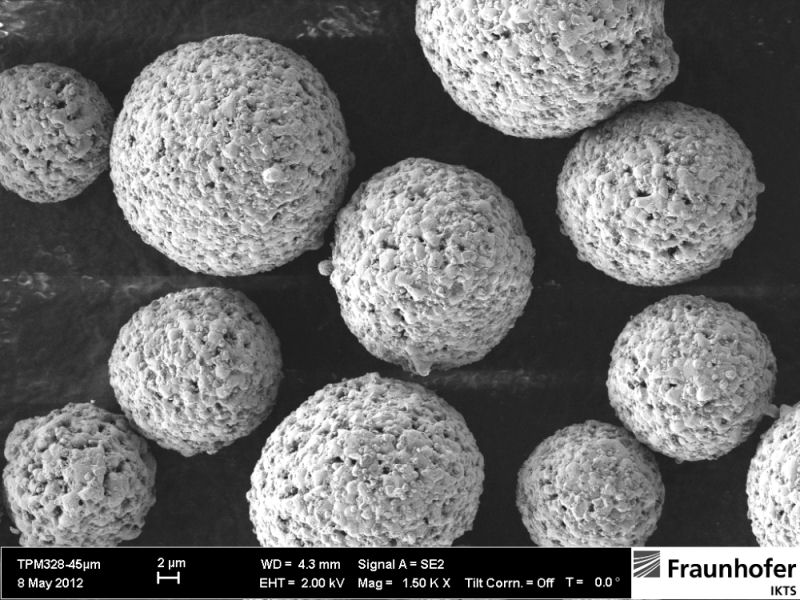

- Development of granules (spray drying) in terms of density and structure, adjustment of porosity, improvement of flowability

- Adjustment of granule properties to spraying methods

- Up-scaling, manufacturing of small batches of coating powders for tests in new applications

- Technology transfer at customer’s site

- Thermal spraying (LPPS, APS, HVOF, PTA) in collaboration with the Thermal Coating working group (Fraunhofer IWS)

- Comprehensive characterization of commercial powders/coatings and development products

Technical equipment

- Technology line ”agglomerated & sintered” (a&s) in laboratory and pilot scale (suspension preparation, spray drying)

Examples and references

- Hardmetal coatings (WC-Co/Ni/Cr/Fe)

- Hard material mixtures with metallic bond ((TiMo)(C,N)-Ni/Co,Cr3C2-NiCr)

- Composite materials (hard material-polymer) for special application

- Ceramic materials for applications subject to wear / corrosion / high temperatures (SiC/Si3N4-Al2O3/Y2O3, YSZ)

- Functional ceramic material mixtures [LSC/LSM powder (SOFC), TinO2n-1, YSZ]