Launch of model region for the implementation of hydrogen technologies

The project network H2-Well for the development of a model region to implement hydrogen technologies on site will be funded over the next five years with approx. 15 million euros from funds of the Federal Research Ministry.

Fraunhofer IKTS part of H2-Well project

The project network H2-Well for the development of a model region to implement hydrogen technologies on site will be funded over the next five years with approx. 15 million euros from funds of the Federal Research Ministry. The application concept, which is backed by around 40 alliance partners from society, research, and municipalities as well as the service sector, trade, and industry, was one of 20 innovation projects to be selected in a complex two-stage selection process for the "WIR - Wandel durch Innovation in der Region" regional funding program in the Eastern states of Germany. The vision of a hydrogen model region is to be promoted together.

The aim of the WIR! funding is to grasp "structural change as an opportunity and not as a risk". And this is exactly how the H2-Well players think: "We see the opportunity not only to promote structural change in our regions with the use of hydrogen technology, but also to protect the climate. We are also actively seizing this opportunity," says project coordinator Prof. Dr. Mark Jentsch from the Bauhaus University Weimar.

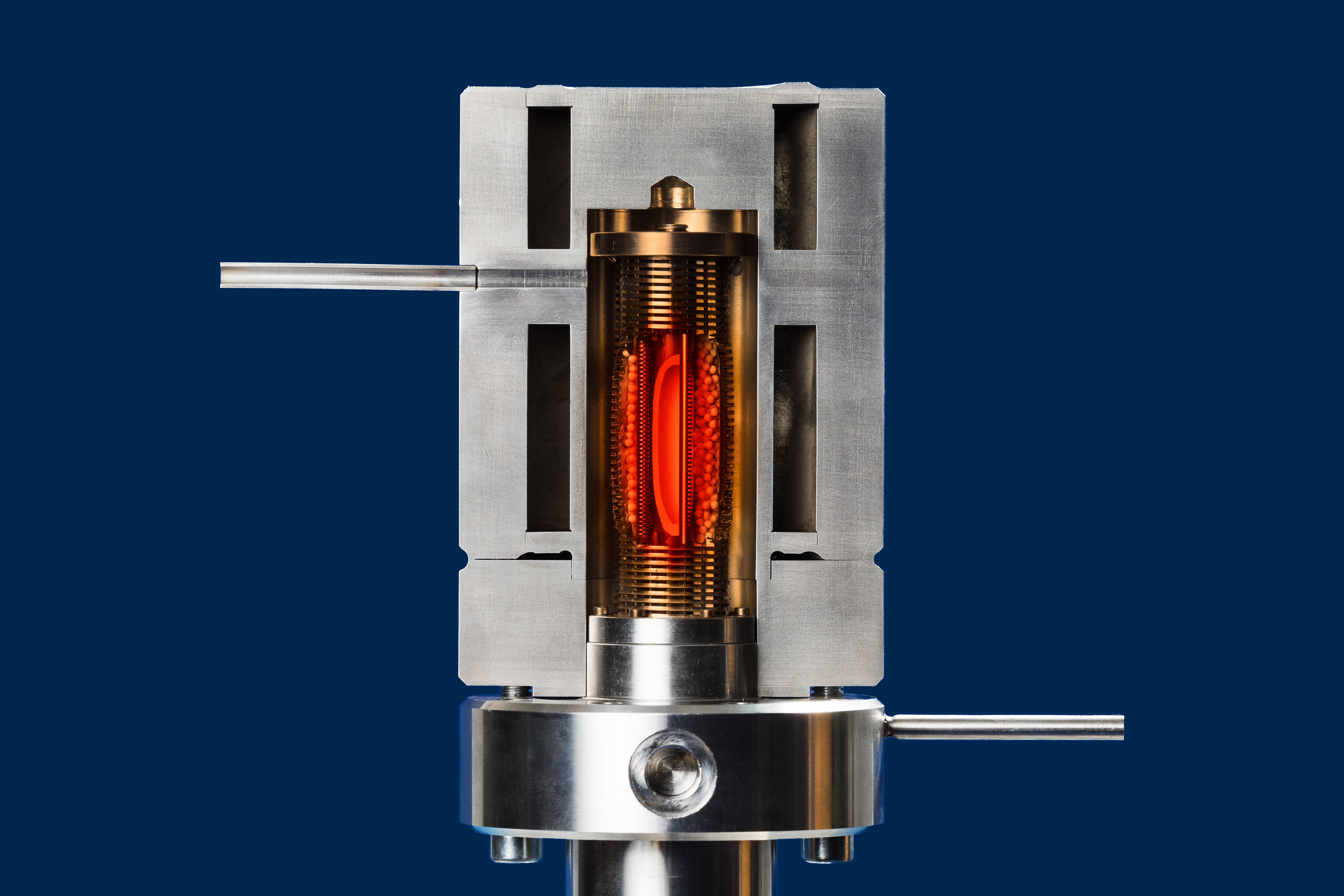

As a project partner, Fraunhofer IKTS is involved in the further development of high-pressure electrolysis. Hydrogen is to be compressed under high pressure of up to 700 bar using a "pump" with a ceramic proton-conducting membrane. This is of particular interest for the supply of hydrogen vehicles in terms of increasing their range. The new technology is intended to replace conventional compressor solutions, which, in comparison, are expensive and susceptible to maintenance, and to support the implementation of hydrogen mobility. On the other hand, the institute is participating in the project to develop new processes to increase the efficiency of water electrolysis and mechanization in the CO2-intensive building material industry. Using a pilot plant, technical scale tests will be conducted to evaluate how the technology can reduce emissions and optimize processes in this sector.