CarbonCycleMeOH

Strategies for a climate-neutral chemical park

How can industrial CO2 emissions be reduced? How can material cycles be closed economically? This is being investigated by a consortium led by Fraunhofer IKTS as part of the CarbonCycleMeOH feasibility study funded by the German Federal Ministry of Education and Research (BMBF), using methanol production at the Bitterfeld-Wolfen Chemical Park as an example. The study will offer process engineering and political recommendations for action to integrate the chemical industry into a renewable energy system.

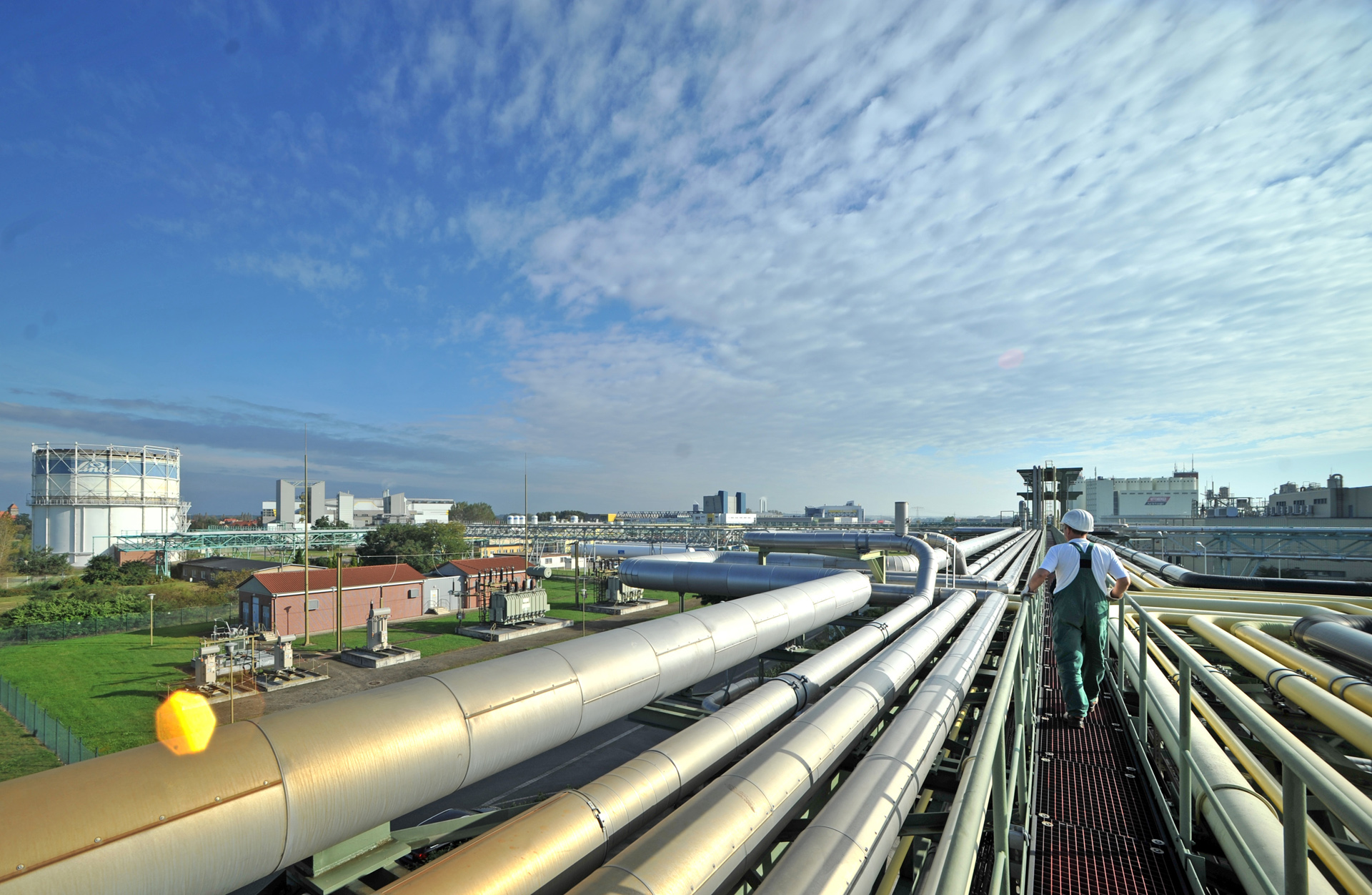

With 1200 hectares, the Bitterfeld-Wolfen Chemical Park is one of Germany's largest chemical sites. Around 300 resident manufacturing and commercial companies benefit here from a highly integrated cluster that offers a secure supply of basic chemicals and technical gases.

Methanol synthesis based on CO2 and green hydrogen from renewable energies

Gas and steam plant, wastewater purification and biomethane plant – CO2 is currently emitted in various thermal, chemical and biological processes at the chemical park. “Establishing a circular economy in which this CO2 is converted into methanol as C1 building block is very promising in terms of reducing CO2 emissions in the energy-intensive chemical industry,” explains Dr. Matthias Jahn of Fraunhofer IKTS, who is leading the project. “As part of the feasibility study, we want to look at this new process chain and develop a concept using electrolysis technologies. The process thus contributes significantly not only to reducing CO2 emissions into the environment, but also to increasing the efficiency of the entire cluster.”

High-temperature electrolysis in particular could prove to be beneficial here, especially in terms of increasing energy efficiency: The use of waste heat streams from other processes at the chemical park and the possibility of converting water vapor directly into suitable synthesis gas using CO2 offer potential advantages here for the process route under consideration.

The study covers the following aspects:

- Assessment of the market environment as well as the regulatory framework

- Analysis of the relevant material and energy flows including usable CO2 sources

- Model-based process development for the expansion of the existing chemical cluster

- Investigation of the necessary infrastructure expansion

- Techno-economic evaluation and life cycle analysis for the developed process concept

- Derivation of political recommendations for action based on the project results