Breakdown of anthropogenic trace substances

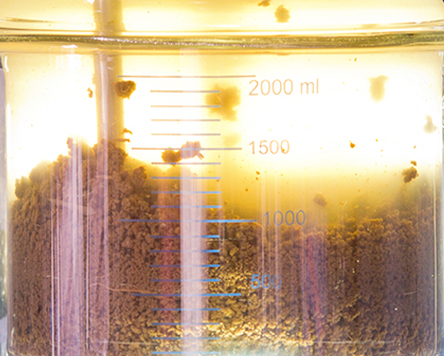

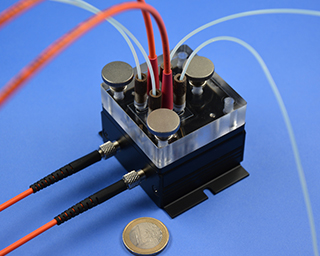

The contamination of water bodies with organic substances of anthropogenic origin – pharmaceutical trace substances in particular – is a growing concern. Effective and efficient elimination is possible with adsorptive, as well as oxidative, processes and process combinations. For the selective removal of pollutants, Fraunhofer IKTS has developed an integrated process combination of activated carbon adsorption and membrane filtration (MF/UF). This combination has already been tested successfully for the elimination of various trace substances, such as Carbamazepine and Diclofenac.

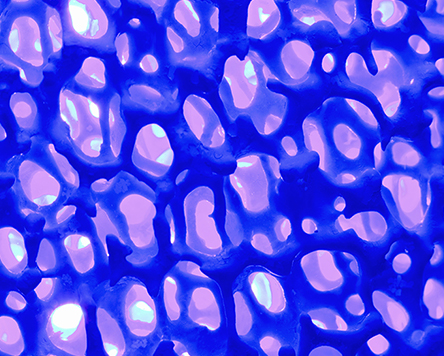

AOP processes, such as photocatalytic or electrochemical treatment processes, are suitable for the complete breakdown of persistent contaminants. To achieve this, Fraunhofer IKTS has developed TiO2-coated cellular ceramics which require lower energy input compared with other AOP procedures, thanks to their large interaction areas and better penetration depth of light irradiation.

Advantages:

- Complete breakdown or selective separation of organic compounds

- Versatile use according to specific needs

- No consumables required

- Regenerable materials

- Simultaneous disinfection possible