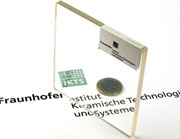

Fine-grained transparent spinel armor (about 10 x 10 cm2, thickness 5 mm).

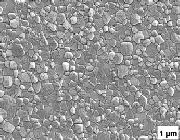

Sub-µm microstructure of transparent spinel ceramic: average grain size 0.42 µm after sintering (HIP) at 1360 °C. Hardness HV10 ≈ 15 GPa.

Improved ballistic strength and transparency by fine-grained micro-structures

Ceramic processing that avoids defects enables the manufacture of clear transparent sintered ceramics which exhibit highest protection.

Advantages

- Al2O3 ceramic with sub-µm microstructure is the hardest known transparent armor: it associates a hardness HV10 > 20 GPa with a real in-line transmission (640 nm, ~ 0.5° aperture) RIT ≈ 70-80% (at thickness ~ 1 mm)

- In fact, the non-cubic lattice of Al2O3 gives rise to scattering losses and a decreasing with larger thickness transparency. Contrary to that, fine-grained spinel ceramics with high hardness (HV10 = 14-16 GPa) exhibit clear transparency even at larger thickness

- These fine-grained spinel ceramics exhibit a similar ballistic strength as the hardest corundum ceramics and outperform sapphire

Products and services offered

- Development of technologies to manufacture transparent ceramic armor, upscaling investigations

- Development of optimized materials for specific applications

- Application related investigations of the ballistic protective performance in cooperation with the Fraunhofer-Institut for High-Speed Dynamics (Ernst-Mach-Institut) Freiburg i.Br.

Areal weight required to stop a projectile (vp = 850 m/s, AP ammunition; tests: EMI Freiburg): Data for glass and glass-ceramic armor and improved ballistic strength by use of thin front tiles of single crystals or ceramics. Fine-grained sintered ceramics (sub-μm Al2O3, spinel) outperform sapphire