Gelcasting – shape variability for ceramics

Current research

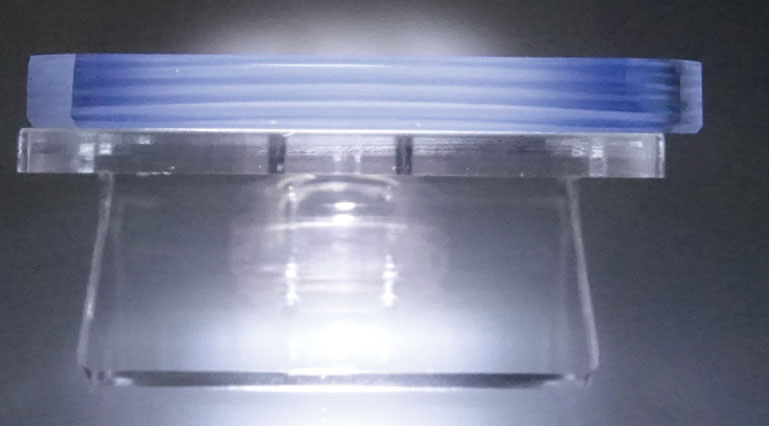

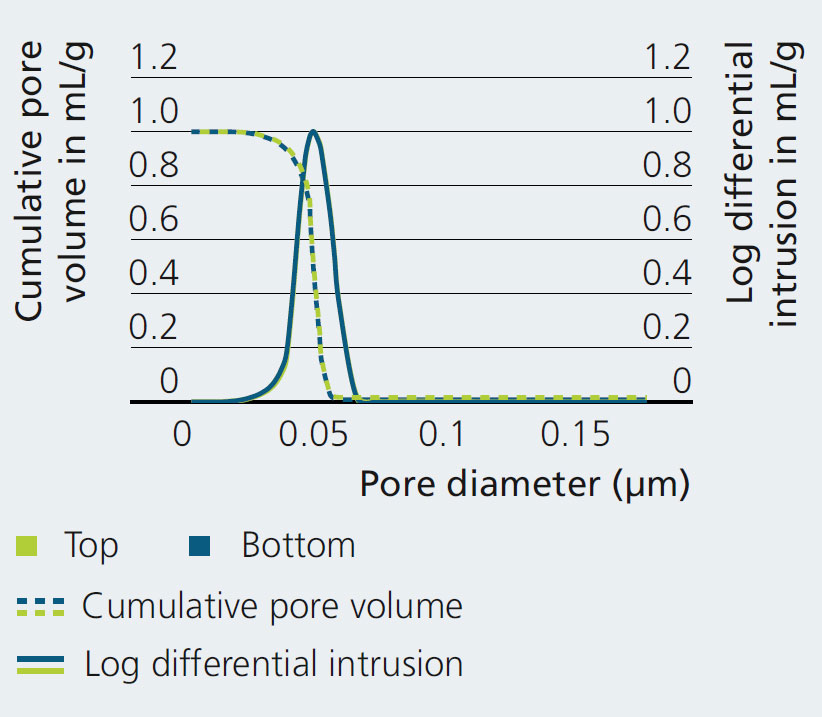

Gelcasting is a versatile shaping method for fabricating dense ceramic parts with a broad variety of geometries at a very low defect level and with high quality. Homogeneous green bodies of all shapes with a high green density between 50 and 65 % and a narrow pore size distribution can be achieved (figure).

A stable suspension with high densification and homogeneity is a prerequisite for gelcasting. This is achieved with an adequate powder/additive combination and tailored powder processing. A suitable monomer system is added to the suspension to polymerize around the particles and absorb the solvent. In the next step this suspension is cast in molds and consolidated by polymerization. The “gel body” is then demolded and must be dried slowly to prevent cracks. The drying stage is followed by heat treatment. The organic parts are burned out first. With pressureless sintering, a theoretical density of up to 99.5 % is achievable, while pressure-assisted sintering puts 100 % within reach.

Shape variability by bulk and multilayer processing

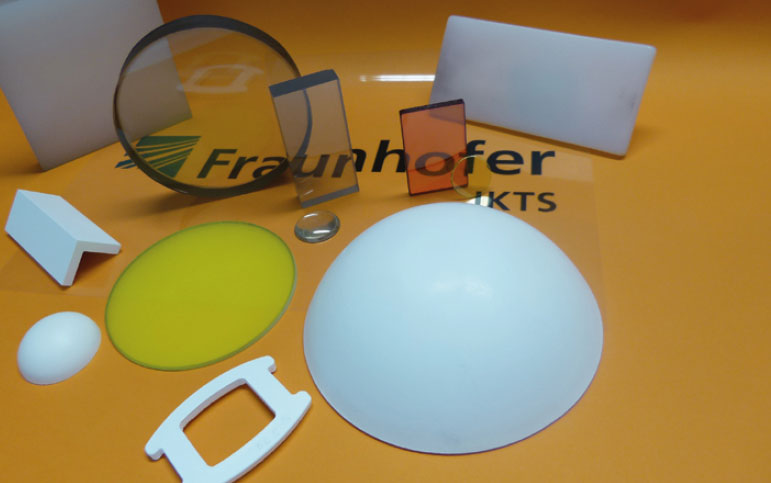

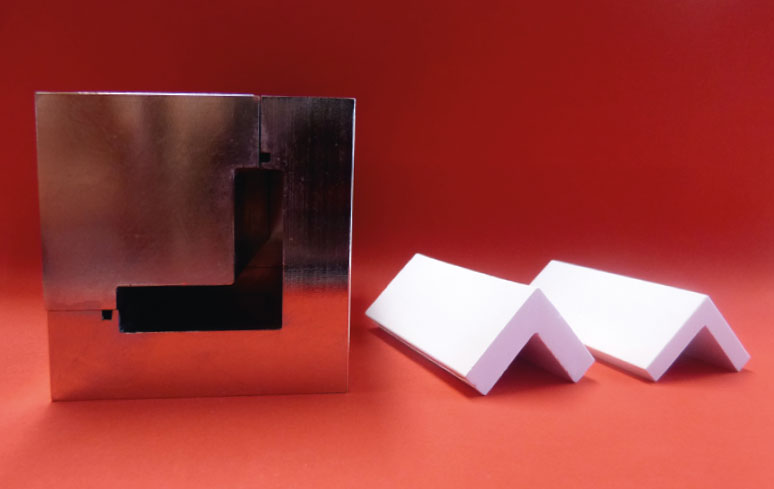

At Fraunhofer IKTS, we have extensive know-how regarding suitable gelcasting suspensions and appropriate molds. This allows to cast ceramic components, which need less finishing treatment after sintering (image 1). By considering shrinkage, molds can be constructed in near-net shape. It is possible to cast a variety of geometries, such as large blanks, geometries with cavities, sharp edges, and angles (image 2–3), as well as small or thin planar components. By tailoring the polymerization process, it is also possible to perform additive gelcasting layer by layer and introduce different elements for doping or varying concentrations. By increasing the concentration of coloring agents or dopants, an individually tailored color gradient can be achieved. This special gelcasting technique is suitable for manufacturing opaque and transparent ceramics. Image 4 shows an example of alternatingly doped MgAl2O4. Gelcasting by layers requires a strong cohesion between individual layers, which is realized though adapted process management.

Services offered

- Suspension development for different raw materials for liquid shaping

- Process optimization for near-net-shape geometries of high-density (opaque and transparent) ceramics

- Development of high-density ceramics with property gradients