Polycrystalline faceted sapphires and rubies (1.5 ct.).

Several stages of sintering of a work piece produced by CNC-green machining.

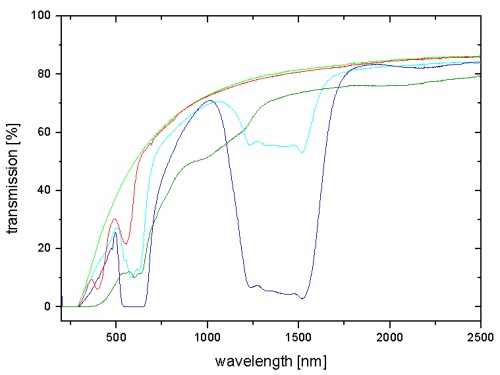

Polished discs with several dopants (thickness: 0.8 mm).

Single crystalline sapphires and rubies have found many uses due to their mechanical, esthetical and optical properties. The production of these materials is, however, rather expensive and the crystals have to be machined for obtaining the desired shape. Furthermore, the application of dopants is often limited by the common approaches of crystal growth. Another disadvantage is the orientation dependence of the mechanically and optically parameters due to the anisotropy of the corundum crystals.

A ceramic sintering technique is used here to overcome these drawbacks. Similar "gemstone" syntheses are known previously for crystallographically isotropic (cubic) materials as spinel and zirconia but not for corundum.

Advantages

- The new sintered materials combine the outstanding mechanical properties of sub-microcrystalline corundum (Vickers hardness HV 10 > 2000, 4-point bending strength >600 MPa) with a new quality of the transparency of coloured sintered corundum (Fig. 3)

- Sintering approaches offers the advantage of flexible shaping (Fig. 2) and enable the development of new functional materials by incorporation of new dopants and pigments into the polycrystalline microstructure

- Due to the randomized orientation of the anisotropic crystallites, the macroscopic sintered bodies become optically isotropic

Products and services offered

- Development of colored transparent ceramics, e.g. based on corundum as well as based on ceramic raw materials with cubic crystal structure. Alternative developments with commercial or with nanoscale raw materials

- Technological investigations for upscaling supporting the development of new products; screening of raw materials and shaping approaches

- Investigation of the technical performance in various applications e.g. esthetically high-grade sintered parts, scintillators, filters and other optical windows with different degrees of transparency in different parts of the spectrum, lighting technology