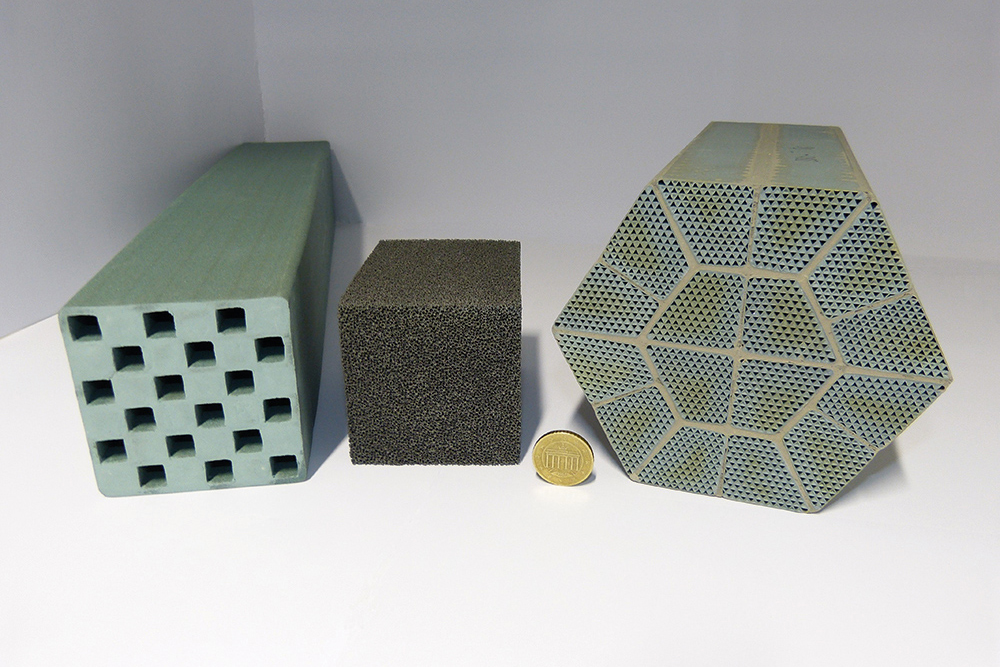

Ceramic filters capable of back-cleaning are used for the dedusting of hot gases and the recovery of recyclable materials from hot exhaust gases at operating temperatures of up to approx. 800 °C and sometimes above. For this application porous ceramic materials used because of their excellent temperature stability and chemical resistance, their mechanical strength and their superb filtration performance.

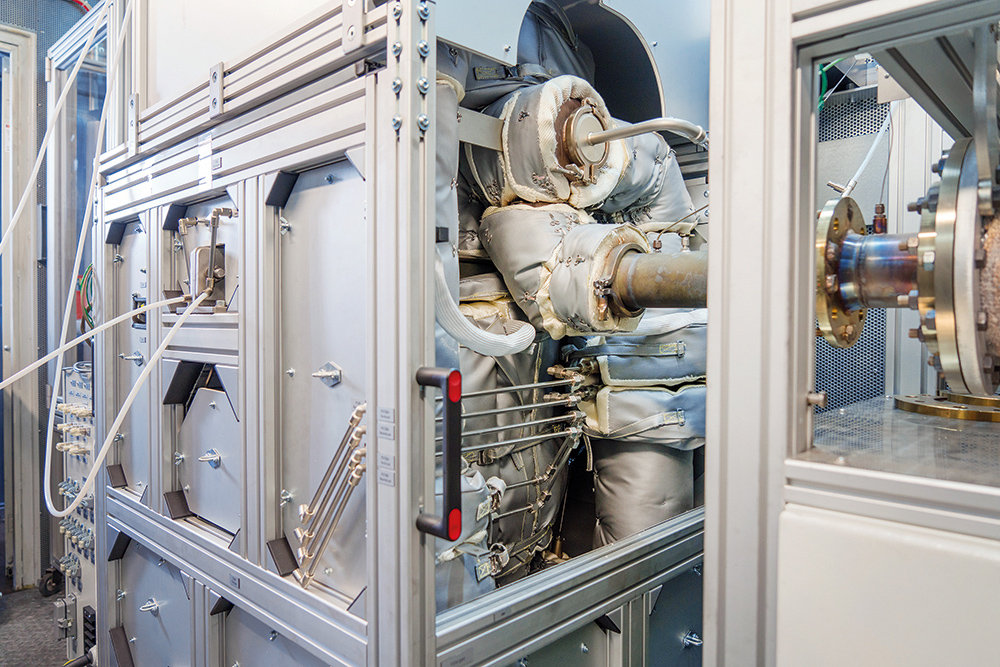

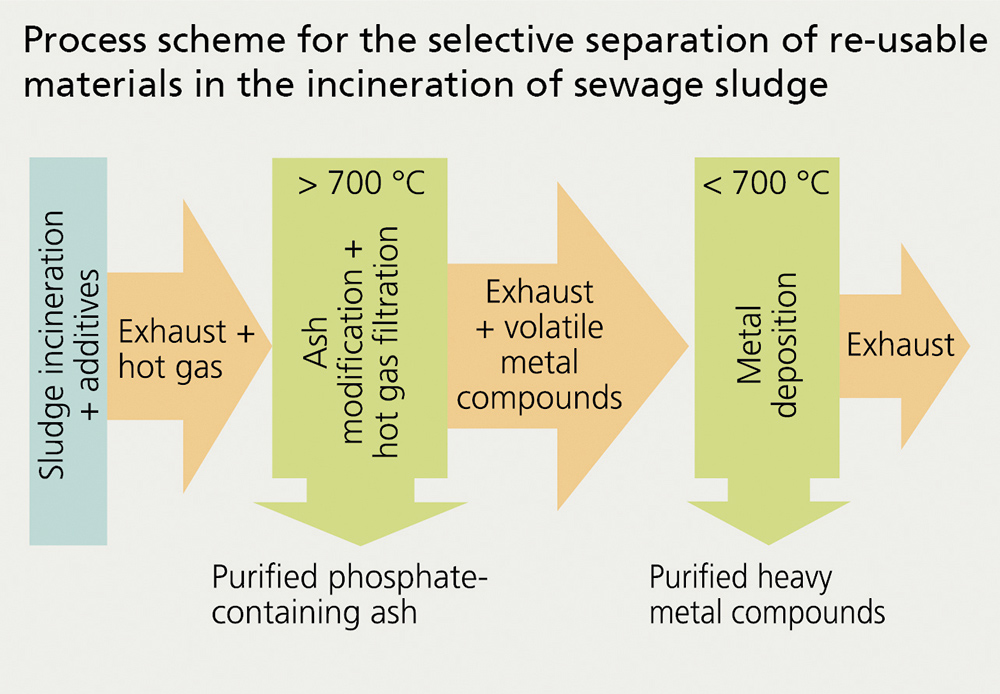

Fraunhofer IKTS develops and improve filter materials for hot gas filtration, technologies for the production of innovative filter geometries, as well as new hot gas filter applications. Current developments are concerned with the hot gas dedusting of exhaust gases from the steel and lime industry. Most recently, the separation and cleaning behavior of various dusts was investigated and the applicability of hot gas filtration was demonstrated with the aid of a special test rig set up for this purpose. By combining this with membrane-supported processes, it is also possible to extract CO2 from hot and dust-enriched exhaust gases. A further process development at IKTS focuses on the environmentally relevant topic of phosphorus recovery from the mono-combustion of sewage sludge. By modifying the sewage sludge with special additives, the heavy metal load of the resulting ash fractions containing phosphate will be significantly reduced. The process is based on the targeted generation of volatile heavy metal compounds that pass into the gas phase at high temperatures and are separated from the combustion ash by hot gas filtration. The corrosive atmosphere in combination with temperatures of up to 1000 °C requires the use of ceramic filters that are particularly resistant to high temperature as well as chemicals attacks. In-situ modification makes it possible to reduce the specific energy consumption required for recovering valuable materials compared with processing the ash separately.

Services offered

- Development and testing of materials and filters for hot gas filtration and exhaust gas catalysis

- Development of manufacturing processes for the industrial production of complex ceramic filters

- Test rig investigations of the hot gas filtration behavior of industrial dusts