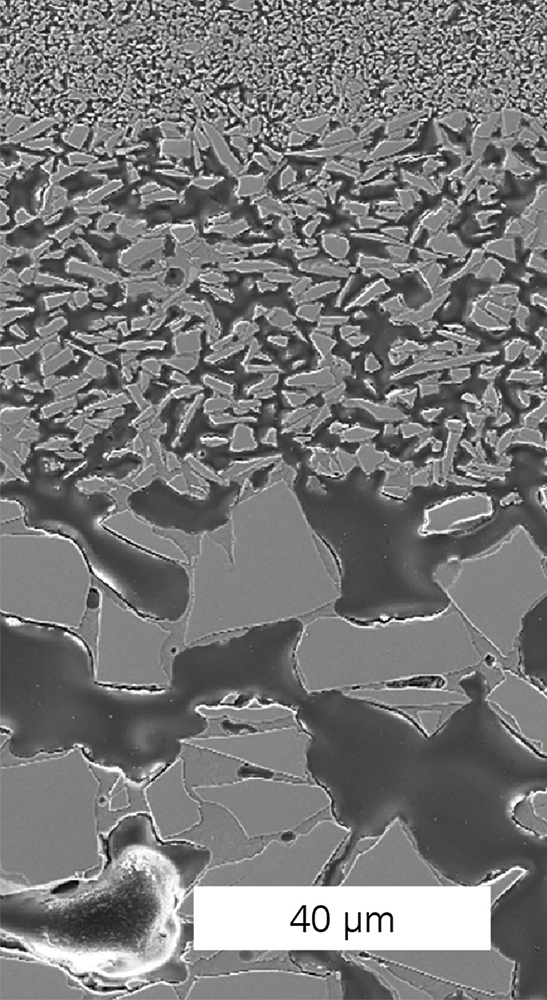

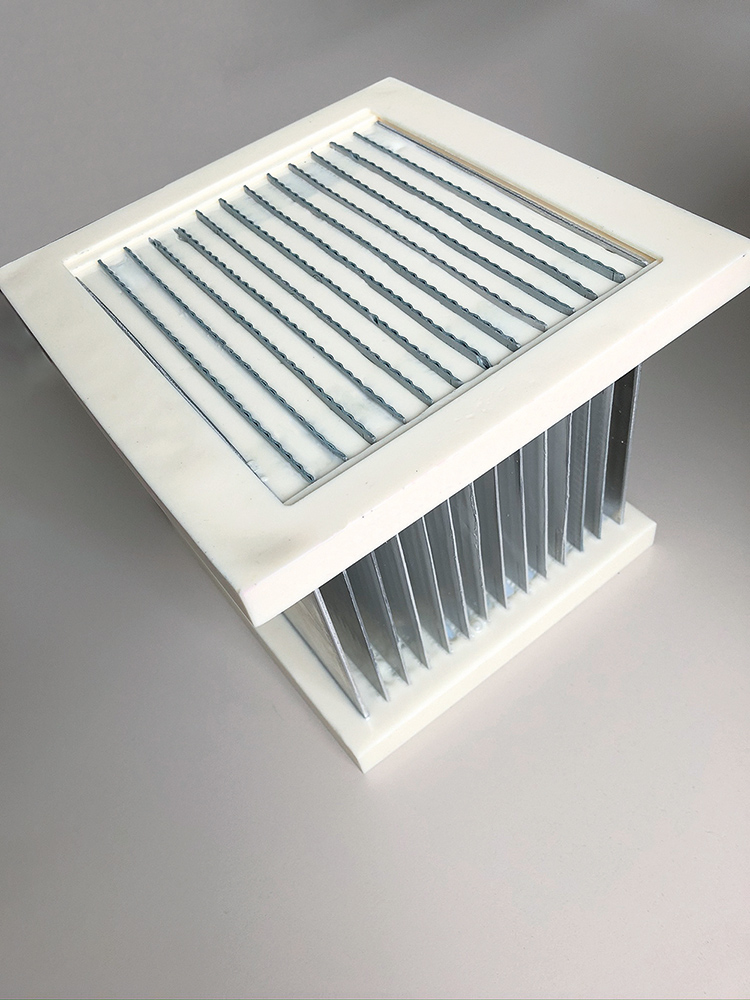

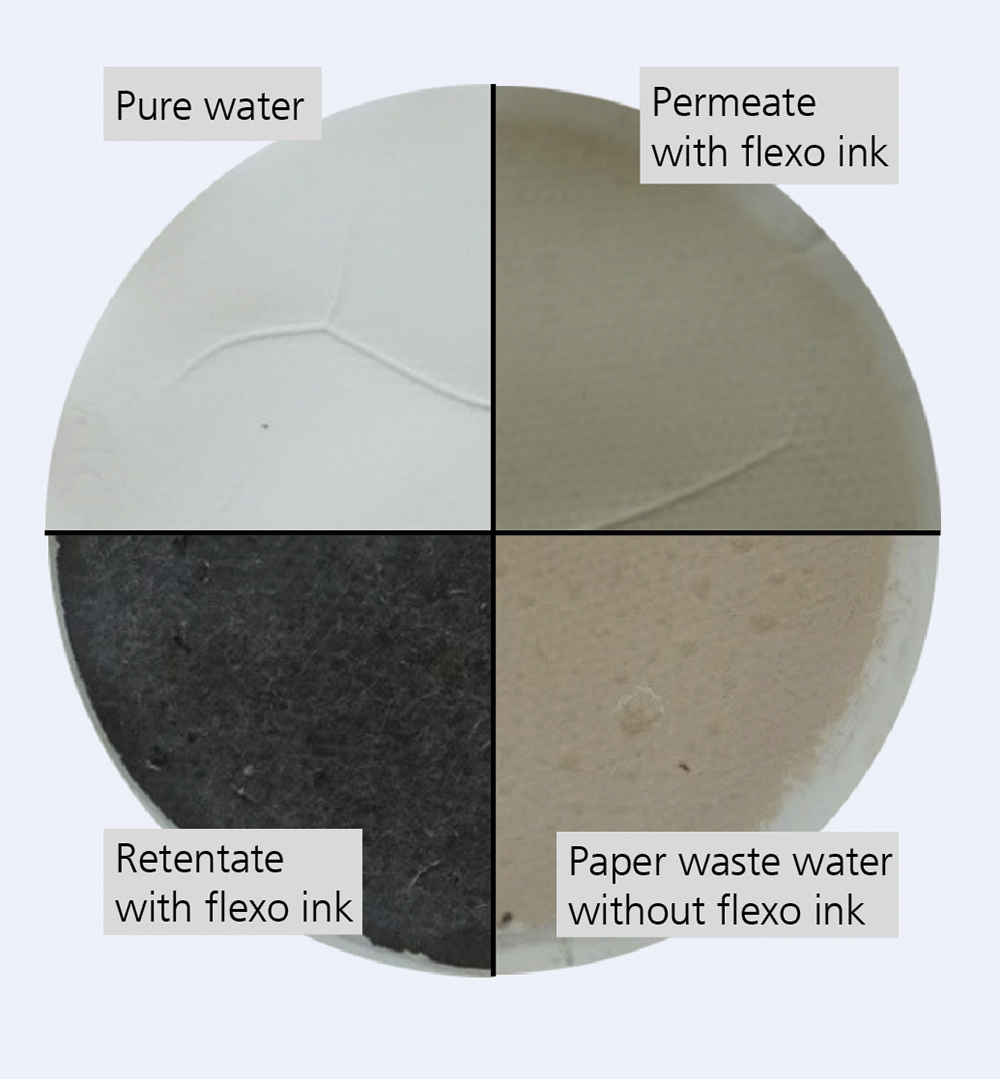

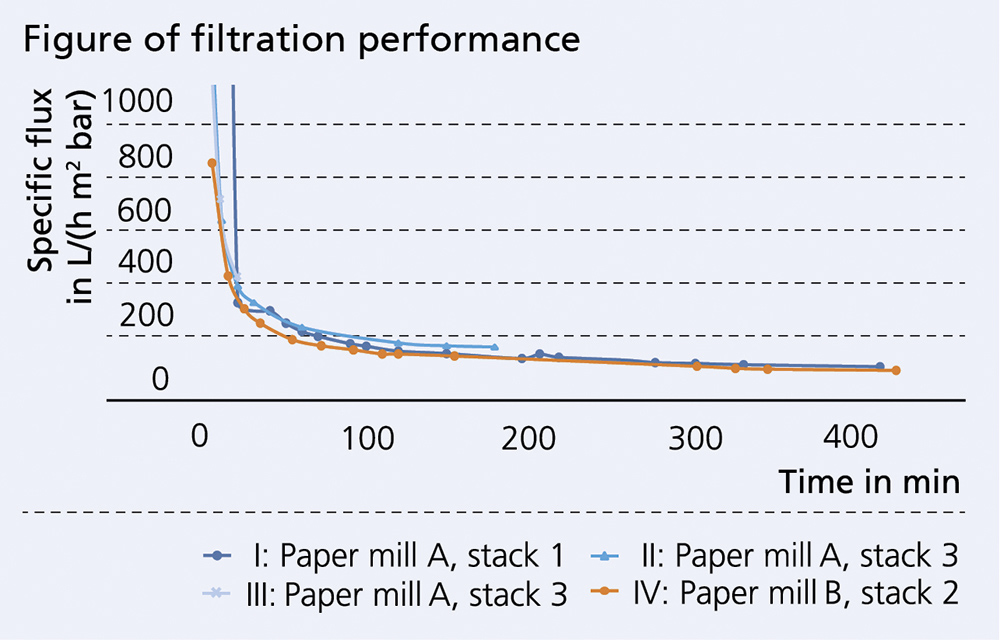

As graphic papers are increasingly produced from waste paper, the removal of printing inks is an essential and indispensable part of the recycling process. Using cost-effective high-performance ceramic membranes, a complementary innovative deinking process was developed at Fraunhofer IKTS, which removes hard to deink or even non-deinkable ink residues in the water cycle of waste paper mills. The need results from a lack of treatment processes in the waste paper cycle and, at the same time, an increase in the amounts of such critical print products. An ongoing AiF project hosted by the pulp and paper industry in cooperation with the TU Dresden managed to determine a ceramic filter configuration for the removal of such colors and investigated it with model and real waters. Corrugated ceramic membranes of glass-bonded SiC are produced by ceramic tape casting, structuring and joining, which allows for subsequent co-firing of the multilayer composition. Finest commercial SiC powders with close grain distributions and D50 values between 0.3 to 1.2 µm were investigated for the dip-coated membrane layer. Evaluative filtration tests with flexo-colored model water found that the SiC powder with D50 = 1.2 μm and the resulting pore size distribution of D50 = 0.25 μm is able to remove flexo-color particles completely. The multichannel elements were used to develop filtration stacks for cross-flow filtration and for use as submerged membranes. Waters from two paper mills were filtered using the different stack variants. As a result, it was possible to achieve a reproducible filtration performance with different water qualities (diagram). In addition, it is possible to reliably produce filtration stacks (Figure 2) with which flexo-color particles can be almost completely retained. The quality of the permeate was also evaluated for turbidity (reduction by 99 %) and concentration of flexo-color particles on the basis of the brightness value “Y” of the test filter paper after permeate flow. The permeate has a Y of 74 compared with pure water, which has a Y of 97, while the recycled water of the paper mill has a Y of 56, compared with the retentate enriched with flexo-ink particles of 12 (Figure 4).

Services offered

- Material and technology development for ceramic membranes

- Filter module development and production

- Upscaling and commercialization