In-line testing of electrode tapes for Lithium-Ion batteries

Current research

High-performance and cost-effective energy storage systems are key components for mak-ing the switch to renewable energy resources. The manufacturing costs of Li-ion batteries for mobile or stationary energy storage can be reduced further by minimizing production defects and resulting scrap rates. Detecting defects at an early stage of the manufacturing process and before further processing ensures the highest possible quality with minimal scrap, making battery production resource-efficient.

LSP for fast in-line defect detection and porosity determination

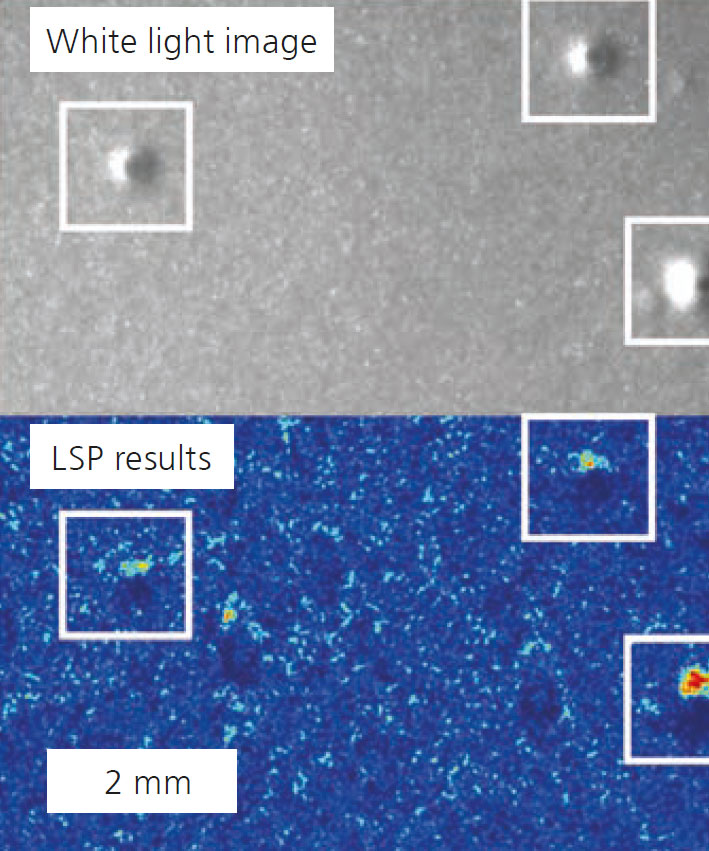

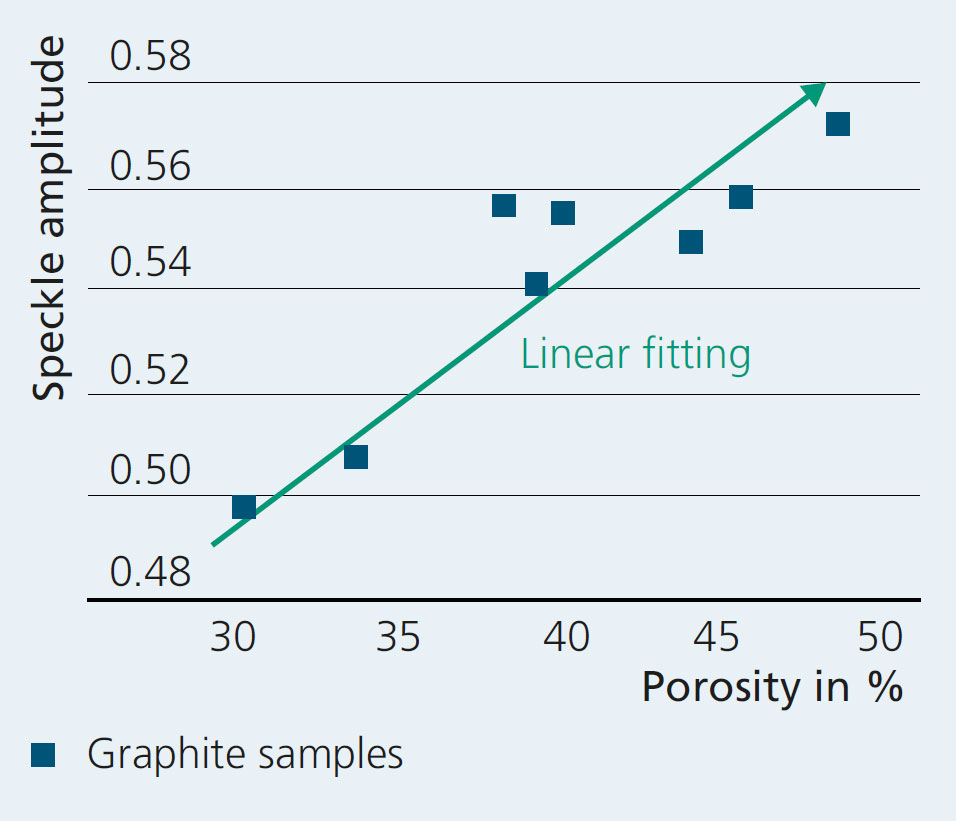

The method of time-resolved laser speckle photometry (LSP) was developed only recently and is suitable for observing optical defects. It allows to determine porosity and surface defects of various types and sizes. Compared with competing measurement methods, LSP is characterized by a simple, robust structure and low costs.

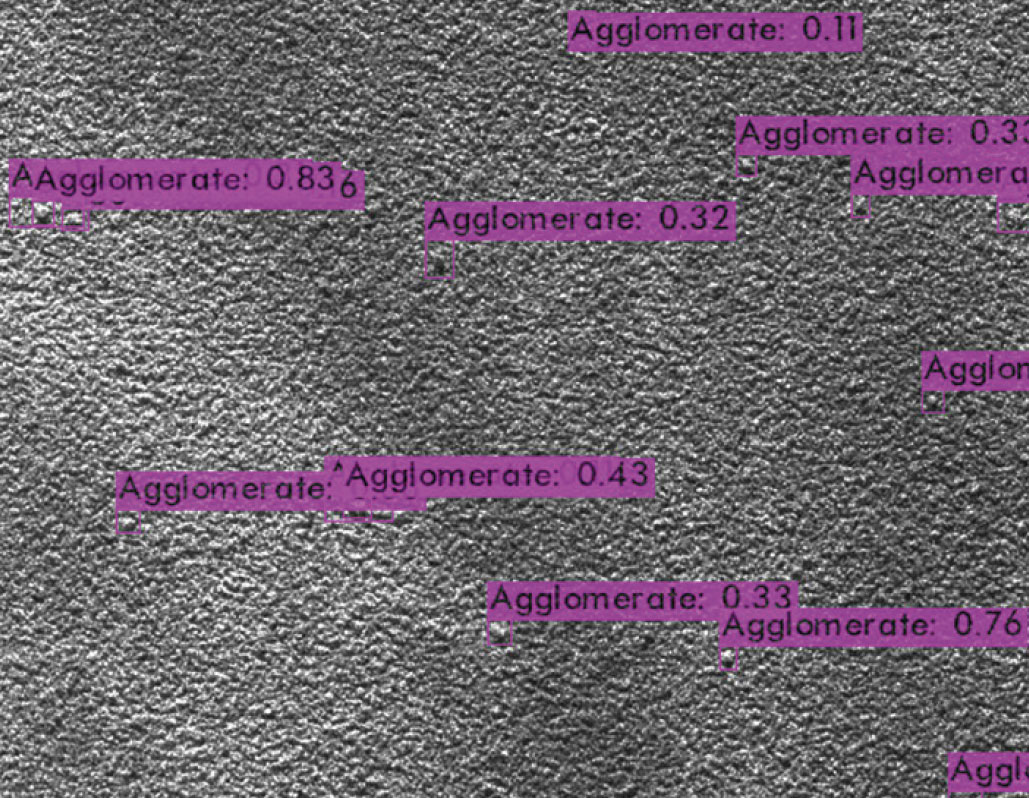

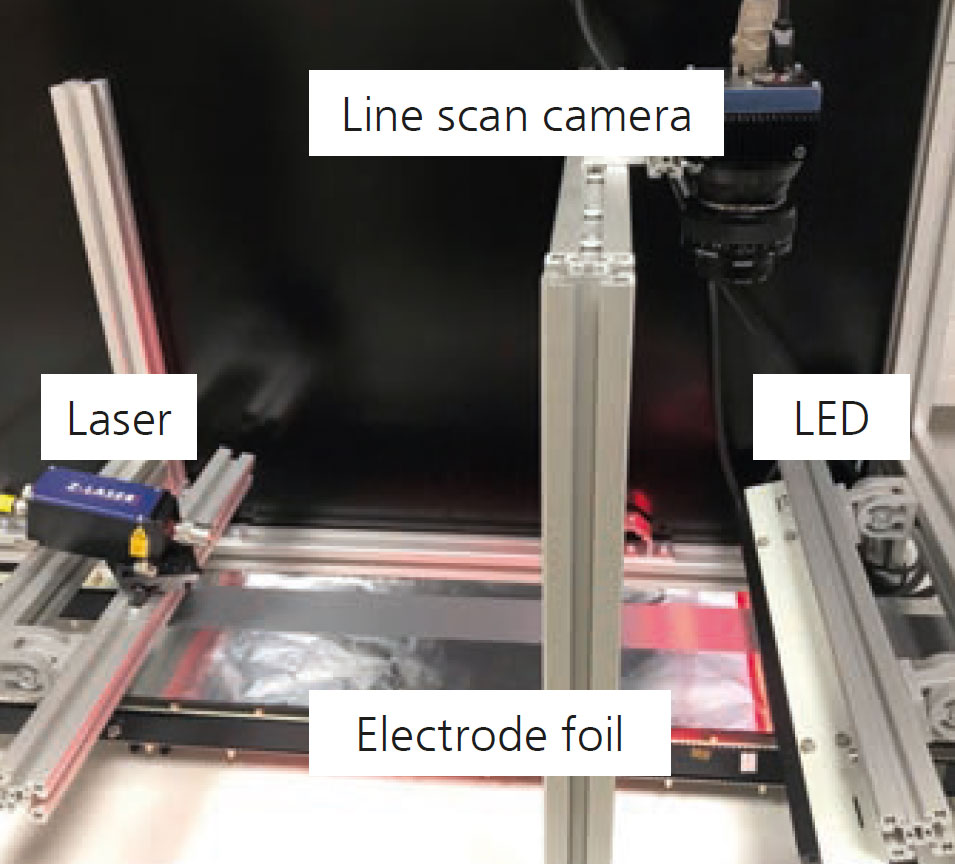

LSP uses a coherent light source, such as a laser, to illuminate the surface being inspected. Unique speckle patterns are generated which contain the morphological information of the surface. The patterns are recorded and processed further by a digital line-scan camera. With the help of image processing and machine learning methods, the defects in the electrode foil can be automatically recognized and classified.

Application in battery production

LSP is used in battery production for the inspection of electrode tapes in roll-to-roll processes. After being stimulated by a laser, the optically rough surface of the electrode tapes provides the patterns required for quality evaluation. A first step consisted in characterizing samples in the form of LTO (lithium titanate) anodes with agglomerates. In addition, if the electrode material is excited by an external thermal source with a short thermal pulse, the porosity can also be determined by evaluating the change of the dynamic speckle patterns. The current experimental setup achieves a measuring speed of 4 m/min for a 16 cm wide electrode tape and agglomerates larger than 70 μm can be detected.

The LSP technology is currently being scaled to a production facility for battery electrodes. This includes drying, calendering and slitting processes.