Ceramic matrix composites (CMCs) combine the advantages of carbon fiber composites (high strength in the fiber direction and simultaneously low weight) with the positive properties of ceramics (high temperature and corrosion resistance and high strength). This qualifies the materials for use in harsh environments, such as high-temperature, corrosive, or very high mechanical loading conditions. Therefore, the primary application for these composites is for highly stressed components, for example, in airplane engines. The obstacles to introduction of CMC technology are similar to those that complicated the introduction of carbon fiber composites. The component behavior over the life cycle of the components and the relevant damage mechanisms are unknown. In addition, non-destructive test methods have not yet become established for these materials.

The suitability of the high-frequency eddy current technology for CMCs is being evaluated in preliminary studies. This work draws on the extensive and lengthy experience of the project team in eddy current testing of pure carbon fiber composites. The test method was evaluated by means of CMC samples from different stages of the manufacturing process.

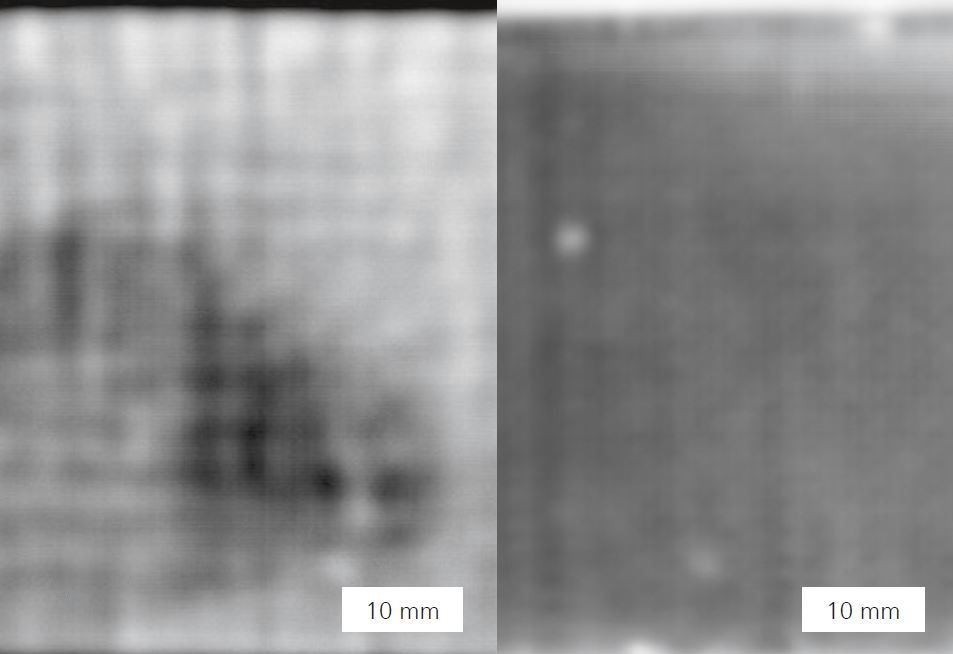

With the eddy current technique, the surface of a test object is scanned with a special probe. In the process, a small and very localized electromagnetic field is coupled with the material and variations in the electrical and capacitive properties of the material are recorded. In this way, the test object can be investigated down to a depth of a few millimeters below the surface. The scan can be performed on flat specimens using a simple 2D scan desk or on freeform components using an inspection robot. Both test systems were developed by Fraunhofer IKTS and are ready for application in industrial environments.

Within the scope of an internal study, the high-frequency eddy current technique was found to be capable of yielding the following characteristics of CMC materials:

- Orientations of individual fiber layers

- Local fiber density distributions

- I nclusions of air (pores) or impurities (depending on the included material)

- Notches, scratches, and cracks

- Local variations in homogeneity of the infiltrate

- Uninfiltrated or poorly infiltrated areas

These results demonstrate the suitability of the high-frequency eddy current technique for use in non-destructive quality control of ceramic matrix composites.