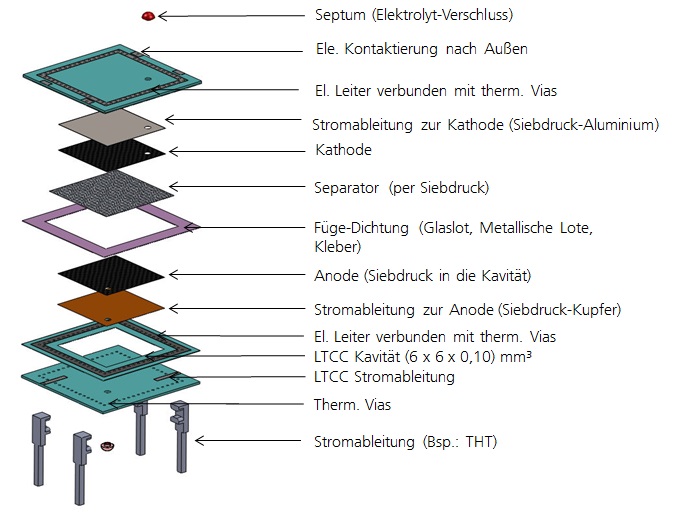

An LTCC micro battery consists of two bonded LTCC half-shells with cavities for electrodes and electrolyte. For a successful battery production following requirements for the LTCC half-shells are necessary:

- Low thickness (<0.5 mm),

- Low content of precious metals,

- Sufficient flatness,

- Manufacturability considering the allowable heat treatment of individual components and

- SMD integration.

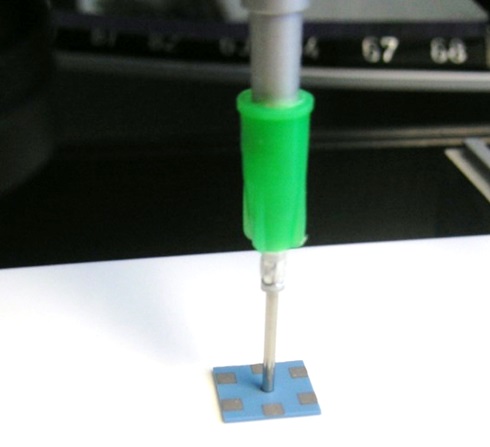

In the illustrated version, the lateral dimension of the battery is (10 x 10) mm² and the depth of the cavity is 100 microns. The electrode covers an area of (6 x 6) mm². The studies on the stability of different LTCC substrates in fluoride-containing electrolyte show that LTCC is very suitable for the production of micro-batteries.

Technical characteristics:

- Total size (10 x 10) mm²

- Complete thickness: (0.7 - 2) mm

- Active area (cavity): (6 x 6) mm²

- Cavity depth 50-100 microns

- Cell voltage of 3.7 V (Li-Ion)

- Capacity: 1.5 - 2.2 mAh/cm

- Bonding of the half shells by gluing or soldering processes (metal, solder, solder glasses)

Services offered:

- Development of ceramic carriers for micro batteries

- Adaptation of housing solutions for applications in the fields of IC or MEMS packaging and energy harvesting