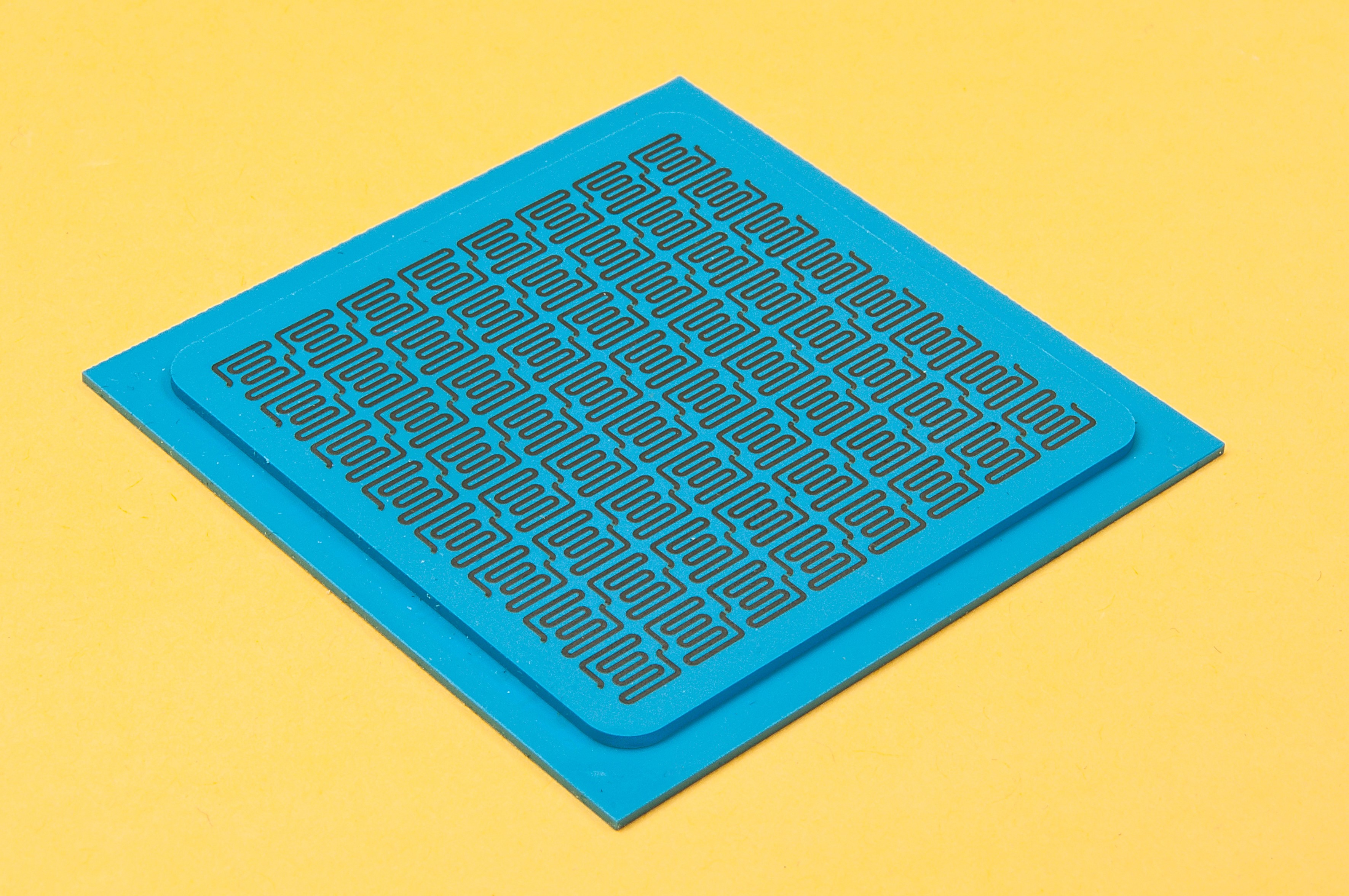

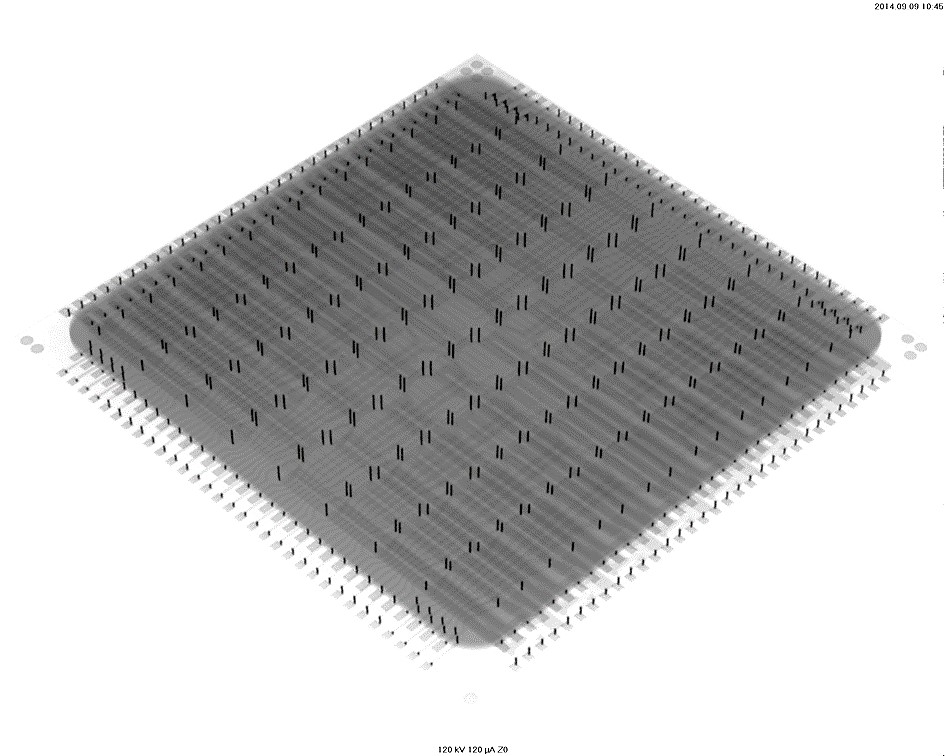

The use of ceramic multilayer technology allows the realization of a high dynamic and efficient heating process to heat local spots on a surface (Figure 1).

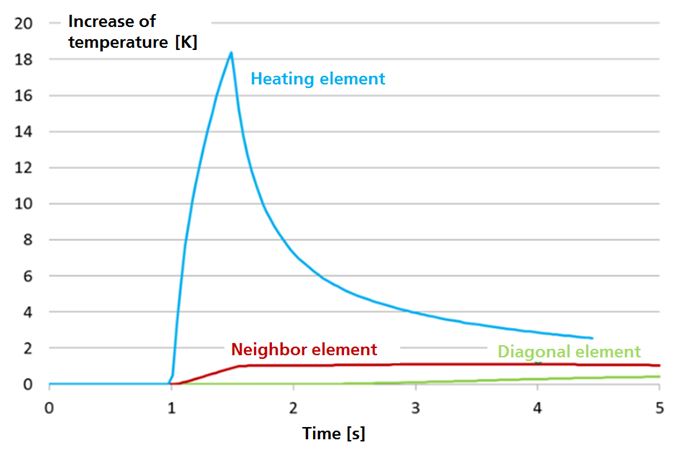

The realized Heating Matrix has 64 individual and controllable heating spots in a selectable form (see figure 4). The diagram in figure 3 shows the results of a heating process of one spot for 0.5 s and its influence on nearby spots.

Furthermore, the multilayer technology enables the monolithic integration of cooling structures. This enables for an additional variance, which has an impact on the temperature gradient.