Eddy current sensors are sensitive to electrical conductive materials, completely contactless. When this principle is implemented as sensors, they can detect path, distance, position as well as velocity. Measurements in highly contaminated environment or of covered objects are easily possible. Typically, eddy current sensors are realized as wire-wound coils. This manufacturing method always implies a certain amount of tolerances and only the fabrication of spiral coils is feasible.

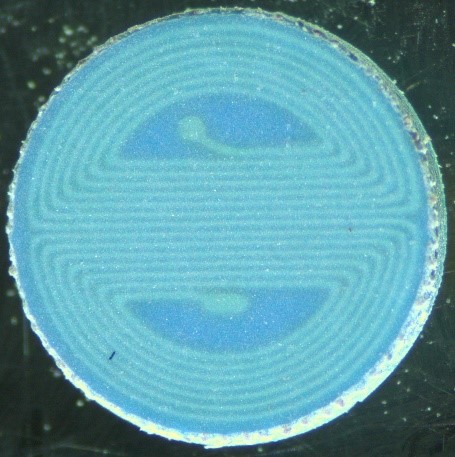

However, the multilayer ceramic technology offers an optimal platform for the flexible integration of eddy current measuring coils with very small designs. LTCC multilayer printed and embedded measuring coils can be used in very rough environments and under operation temperatures up to 350° C. The coil is typically located in the head of the sensor. A crucial element for its performance is the quality factor of the embedded coil. Due to the use of novel LTCC-manufacturing processes (developed at Fraunhofer IKTS) the lateral wounding distance of the printed coils can be reduced to 25 µm. The metallization thickness can be simultaneously enhanced which reduces the internal resistance as well. Thus, the inductivity and the ohmic resistance achieve an obvious optimization that results in significant improvement of the quality factor of the novel coils compared to standard technologies. Embedded micro coils have a sintered metallization aspect ratio of more than one and thus an optimal performance differing clearly from prior art.

The developed LTCC coil technology is inserted e.g. in turbocharger speed sensors of the Jaquet Technology Group for measuring of turbochargers speed for passenger cars and trucks. The measurement and control of turbochargers speed provides the key enabling technology for the optimal regulation of airflow into the engine and therefore to improve the fuel economy and reduction of engine emissions. Due to the compact construction of the coil, the high quality factor and reliability as well as the innovative design the LTCC coil are optimal suited for example for speed sensors systems.

Technical characteristics

- Embedded planar coil line/space: 50 µm/25 µm,

- Stacked coil structure (up to 10 layer) with min. 50 µm vertical metallization distance,

- Smallest component sizes (Min. 01005),

- Aspect ratio of internal metallization of ≥ 1

Services offered

- Customer service concerning manufacturing options in LTCC,

- Custom-built design,

- Elaboration and qualification of manufacturing processes,

- Manufacturing of samples,

- Technology transfer