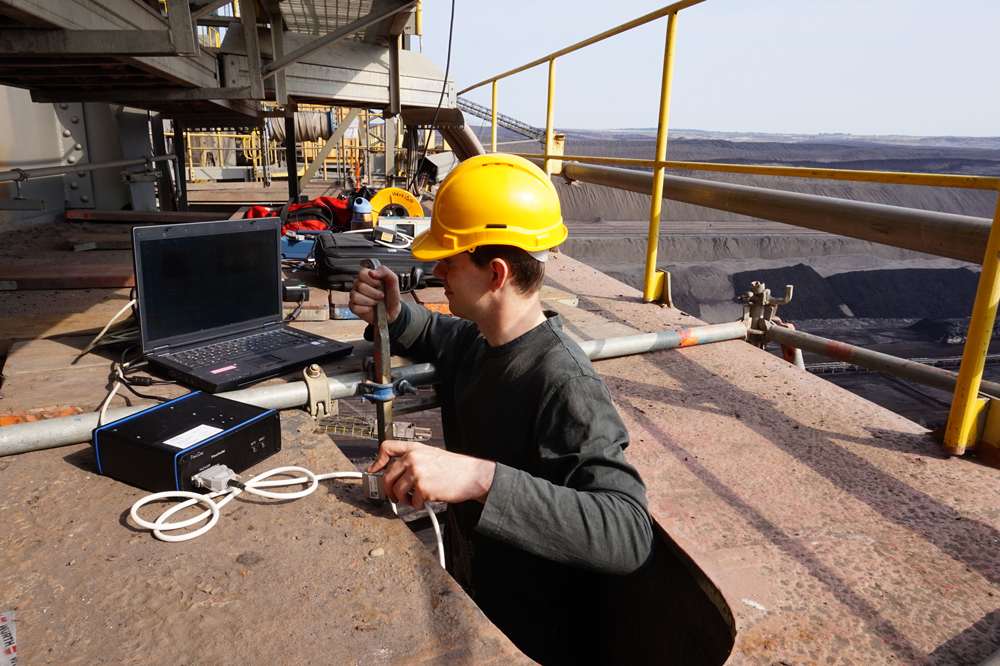

Material fatigue is one of the most frequent causes of costly repair and downtime for large ferromagnetic components in refineries, power plants, plant engineering, but also civil infrastructures. To ensure the long-term use of plants and equipment, scientists at the NDT Test Lab are further developing and applying micromagnetic testing methods that are best suited for ferromagnetic materials.

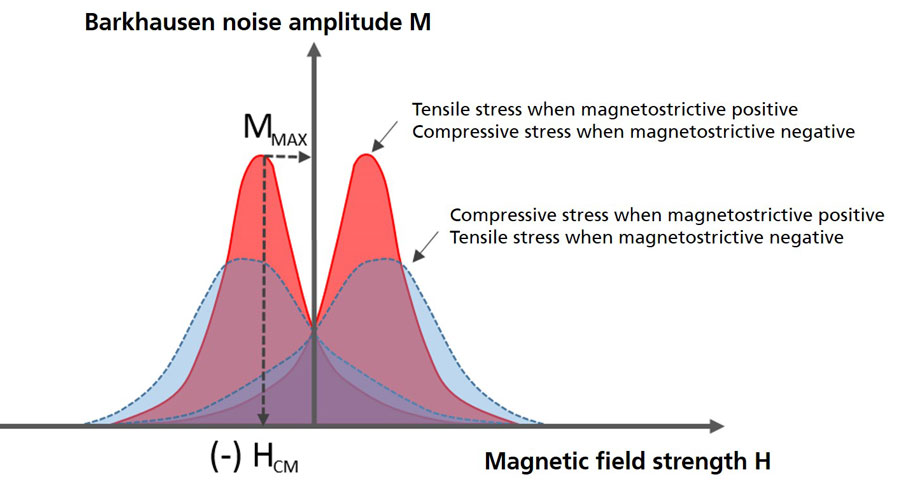

Barkhausen noise is one such method used at the NDT Test Lab to characterize ferromagnetic materials. With a detection depth of 1 cm it belongs to the surface methods. Barkhausen noise is mainly used for the non-destructive analysis of properties such as surface hardness, surface stresses, fatigue state or microstructures.